PRODUCTS

C110 Jaw Plate Factories – JAW PLATES FOR MINING INDUSTRY – Jinhua

C110 Jaw Plate Factories – JAW PLATES FOR MINING INDUSTRY – Jinhua Detail:

Description

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time.

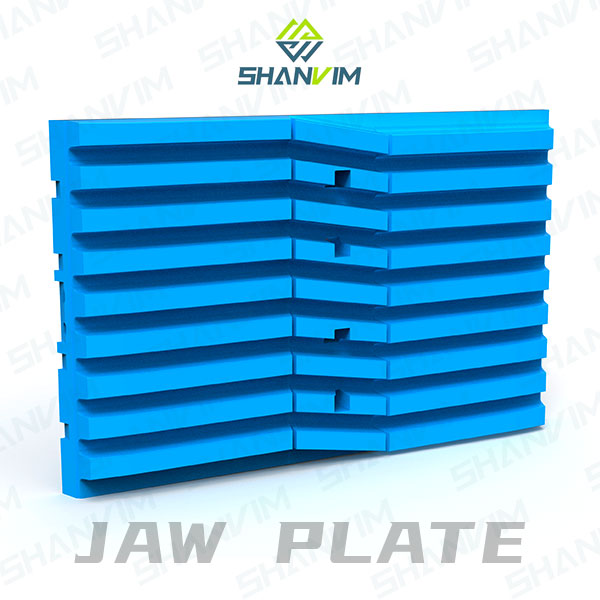

A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing crushing in a jaw crusher is achieved when the movable jaw die presses the feed against the fixed jaw die. The rock remains in the jaw of the crushing machine until it is small enough to pass through the gap towards the bottom of the jaws.

SHANVIM® manufactures, stocks and supplies “Genuine Alternative” jaw plates of a fully extensive range of OEM jaw crushers including but not limited to: Metso®, Sandvik®, Extec®, Telsmith®, Terex®, Powerscreen®, Kleemann®, Komatso®, Kemco®, Finlay® and Fintec®.

Notice: The following table does not include all the OEM interchangeable jaw plates that we can produce. If you need accessories from other brands, or know the OEM serial number of the jaw plate that you are looking to replace, or can provide the drawing of the jaw plates that you need to customize, please feel free to contact us by email or call.

SHANVIM® Alternative Jaw Plates Available For Below Brands & ModelsCollapse

Both stationary and movable jaw die could be flat surfaced or corrugated. In general, jaw plates are made of high manganese steel which is the dominant wear material. High manganese steel is also known as Hadfield manganese steel, a steel whose manganese content is very high and which possesses austenitic properties. Such plates are not only extremely tough but are also quite ductile and work-harden with use.

We offer jaw plates in 13%, 18% and 22% grades of manganese with chromium ranging from 2%-3%. Check below table of our high manganese jaw die properties:

Product detail pictures:

Related Product Guide:

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for C110 Jaw Plate Factories – JAW PLATES FOR MINING INDUSTRY – Jinhua , The product will supply to all over the world, such as: Hongkong, Anguilla, Muscat, Now, we professionally supplies customers with our main products And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.