PRODUCTS

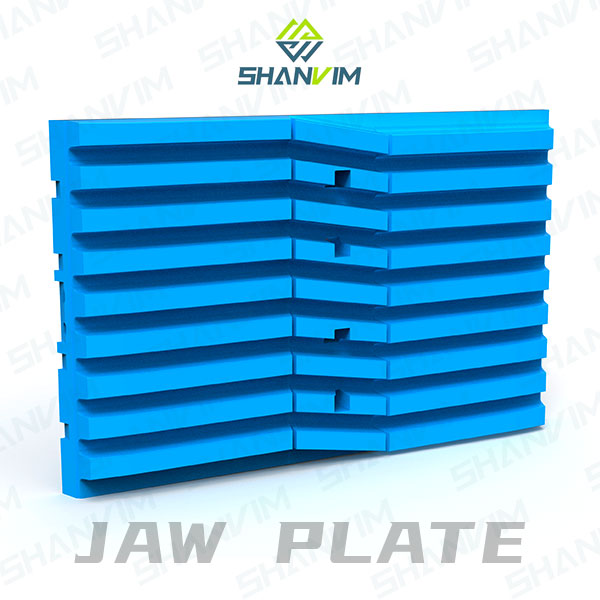

High Quality China Jaw Plate, Impact Plate, Hammer Head, Cone Mantle

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for High Quality China Jaw Plate, Impact Plate, Hammer Head, Cone Mantle, Because we stay with this line about 10 years. We got most effective suppliers support on excellent and cost. And we had weed out suppliers with poor high quality. Now several OEM factories cooperated with us too.

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for China Spare Part, Crusher Parts, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our items to the world together. Trust us and you will gain more. You should feel free to contact us for more information, we assure you of our best attention at all times.

Description

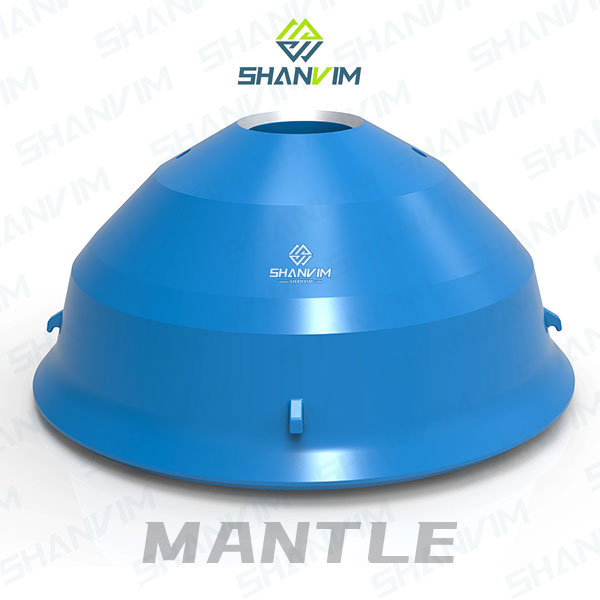

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle and bowl liner.

The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head.

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper accessories of the cone crusher.

SHANVIM® cone crusher mantle and bowl liner are engineered to improve efficiency and reduce costs by extending wear life and minimizing downtime.

① We offer OEM interchangeable cone crusher parts & liners;

② We offer a variety optional materials of cone crusher mantles and bowl liners;

③ We produce more wear-resistant products;

④ We extend the service life of the mantle and bowl liner;

⑤ We provide more competitive prices;

⑥ We provide more professional services and suggestions.

SHANVIM® manufactures stocks and supplies “Genuine Alternative” cone crusher parts of an extensive range of OEM including but not limited to: Metso®, Sandvik®, Extec®, Telsmith®, Terex®, Powerscreen®, Flsmidth® and others.

Notice: The following table does not include all the alternative genuine accessories that we can produce. If you need accessories from other brands, or know the OEM serial number of the mantle or bowl liner that you are looking to replace, or can provide the drawing of the parts that you need to customize, please feel free to contact us by email or call.

Metso®Collapse

|

Nordberg Symons |

Nordberg Omnicone |

Nordberg HP Series |

Nordberg GP Series |

Nordberg MP Series |

Metso MX Series |

Lokotrack LT Series |

|

2′ |

1144 |

HP100 |

GP100 |

MP800 |

MX3 |

LT200HPS |

|

Terex Powerscreen |

Terex Finlay |

Terex Cedarapids |

Terex Cedarapids |

|

1000 Maxtrak |

C-1554 |

TC1000 |

TGS120 |

|

Flsmidth Raptor Series |

Telsmith Titan Series |

Telsmith SBS & SBX Series |

McCloskey C Series |

|

Raptor 200 |

T200 |

38 SBS |

C2 |

High Manganese Steel Cone Crusher Mantle & Bowl Liner

The mantle and concave are often made of austenitic manganese steel, a material well known for its work hardening capability.

We offer cone crusher mantles and bowl liners in 13%, 18% and 22% grades of manganese with chromium ranging from 2%-3%.

|

Material |

Chemical Composition (%) |

Machanical Property |

||||

|

|

Mn |

Cr |

C |

Si |

Ak/cm |

HB |

|

Mn13Cr2 |

12-15 |

1.7-2.2 |

1.15-1.25 |

0.3-0.8 |

>140 |

≤220 |

|

Mn18Cr2 |

17-19 |

1.8-2.2 |

1.15-1.3 |

0.3-0.8 |

>140 |

≤230 |

|

Mn22Cr2 |

21-23 |

1.8-2.2 |

1.1-1.4 |

0.3-0.8 |

>140 |

≤240 |