PRODUCTS

Metal Crusher Shredder Hammer Manufacturers – BOWL LINER-CONE CRUSHER ORIGINAL PARTS – Jinhua

Metal Crusher Shredder Hammer Manufacturers – BOWL LINER-CONE CRUSHER ORIGINAL PARTS – Jinhua Detail:

Description

Cone Crusher Parts Product Details:

- Cone crusher is widely used in metallurgy, construction, mining and other industries, can be used as two broken or three, four broken. Hydraulic cone crusher, composite cone crusher, cone crusher various consumable parts collectively referred to as cone crusher parts.Our foundry supplies many brands cone crusher wear parts, such as concave, bowl liner.Also, we can manufacture the parts which you send us the drawings.

- Mn13Cr2 Cone Crusher Wear Parts

We use the Mn13Cr2 to cast cone crusher parts. Decrease the content of element “Mn” and”C”,and add more “Cr” element. By use this material,it can make up the shortcomings of the traditional high manganese steel toughness, effectively extending the service life of wear-resistant parts.

- Mn18Cr2 Cone Crusher Wear Parts

Using Mn18Cr2 material, the compound metamorphic treatment, grain refinement, purification of grain boundaries; casting solidification control methods to optimize the heat treatment process, casting high hardness, toughness, impact resistance, suitable for large and medium-sized cone crusher jobs

- Donec vel turpis faucibus nisi pellentesque mattis eget in orci. Duis mattis blandit tristique. Mauris lacinia nunc ut libero sagittis lacinia. Aenean fermentum elementum magna. Maecenas aliquam nisi urna, nec eleifend tortor maximus eget. Aliquam vulputate dui vitae nisi fringilla, quis vestibulum libero dapibus. Integer id sodales lorem. Quisque in finibus ante. Nullam at tempus ipsum. Suspendisse potenti. Morbi rutrum eget ipsum sed mollis maecenas blandit euismod urna, eu sodales leo maximus vitae.

- Mn22Cr2 Cone Crusher Wear Parts

We manufacture cone liner for Australia clients by this material,after their feedbacks, it has more span life.

- Tic Insert Alloy Steel

The use of low-cost high-manganese steel or super-high manganese steel for large wear-resistant parts of the base material, composite parts in their work inlaid carbide, the bimetal composite wear parts wear surface has excellent wear resistance, non-wear Mask has excellent plasticity and impact toughness, reducing the wear of the matrix of high manganese steel, so that the cone liners and bowl liners greatly increased service life.

We Can Supply Following Brands:

- Metso Cone Crusher PartsG Range – G49 | G58 | G108 | G138 | G158 | G208 | G258 | G411 | G811 | G1211 | G1811 | G2011 | G2211 | G2511 | G3511 | G412 | G612 | G1012 | G1812 | G2612 | G3812 | G3514 | G4214 | G415 | G815 | G1315 | G2215 | G3815 | G5015

GP® Range -GP100S | GP100 | GP200S | GP200 | GP300S | GP300

Metso HP®- HP100 | HP200 | HP300 | HP400 | HP500 |HP700 |HP800 |HP3 |HP4 |HP5

Metso MP® -MP800 |MP1000 - Telsmith Cone Crusher PartsGyrasphere® – 24″ | 36″ |38″ | 44″ | 48″ |52″ | 66″

- Sandvik Cone Crusher PartsCH® Series -CH430 | CH420 | QH330 | CH660 |CH880 | CH780Hydrocone® 1800 Series -H2800 | H3800 |H4800 | H6800 | H8800 |H7800

Hydrocone® 1000 Series -H2000 | H3000 | H4000 | H6000 | H7000 |H8000

Superior® CS Series – CS420 | CS430 | CS660 | CS440

Superior® 1800 Series – S2800 | S3800 | S4800 | S6800

Superior® 1000 Series – S2000 | S3000 | S4000 | S6000

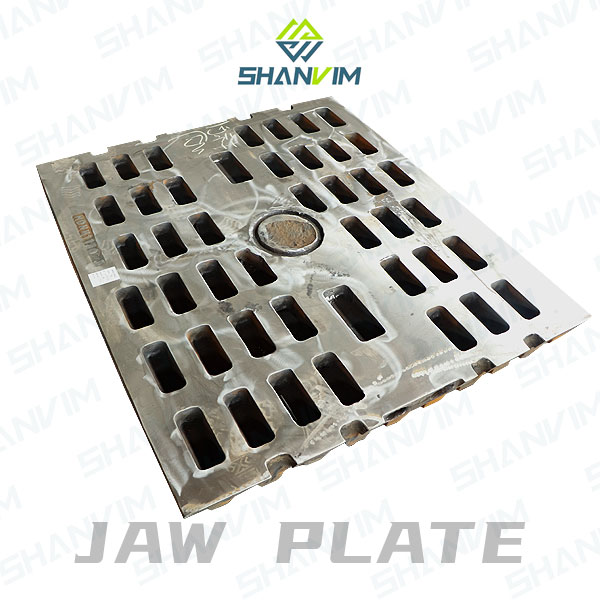

Product detail pictures:

Related Product Guide:

We emphasize enhancement and introduce new solutions into the market just about every year for Metal Crusher Shredder Hammer Manufacturers – BOWL LINER-CONE CRUSHER ORIGINAL PARTS – Jinhua , The product will supply to all over the world, such as: Buenos Aires, Finland, Liberia, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!