News

-

Casting process V-method has six advantages for producing wear-resistant castings

1.The surface of the casting is smooth and has good appearance quality, reduces the adverse effects of appearance defects, and is beneficial to improve the wear resistance; because the sand mold is always kept in a vacuum state, the cavity is not easily deformed, which is beneficial to filling t...Read more -

Shanvim-Tell you what to pay attention to in jaw plate casting?

The jaw crusher relies on the jaw plate for the material processing . Jaw plate is divided into a swing jaw plate and a fixed jaw plate. However, no matter which jaw plate is used, its quality is related to its process. Whether the production process can proceed smoothly, production efficiency, m...Read more -

Shanvim – How to Choose Cone Crusher and Impact Crusher in the Secondary Crushing

For Impact Crusher and Cone Crusher, both used for secondary crushing, the significant difference between them is the crushing principle and appearance structure, which is easy to distinguish. The principle of impact crushing is adopted for impact crusher. Specifically, materials are repeatedly i...Read more -

The Material of the crusher hammer

As we all know, the wear parts in the crusher can have a great impact the mechanical properties. In most cases, if the machine does not work, it is because important parts, such as hammer, are damaged. The material of the hammer directly affects the service life of the crusher. How does the mate...Read more -

How to effectively prolong the service life of a cone crusher?

For the industry insiders, the cone crusher is good in use effect, with high production efficiency and better crushing effect. However, the high efficiency operation largely depends on regular and good maintenance and overhaul. This is the same case for its service life. The crushing equipment u...Read more -

How to effectively extend the life of cone crusher?

For people in the industry, they all know that the cone crusher has good use effect, high production efficiency, and good crushing effect. However, its high-efficiency operation is based on regular maintenance and overhaul, and its service life is the same. It is inseparable from good maintenance...Read more -

Cone Crusher – The knowledge of the daily maintenance

A cone crusher is suitable for crushing various mid-hard and above mid-hard ores and rocks. It is widely used in sand and gravel crushing and other sectors. Like other equipment, the cone crusher also needs careful maintenance. The following is the knowledge related to the daily maintenance of co...Read more -

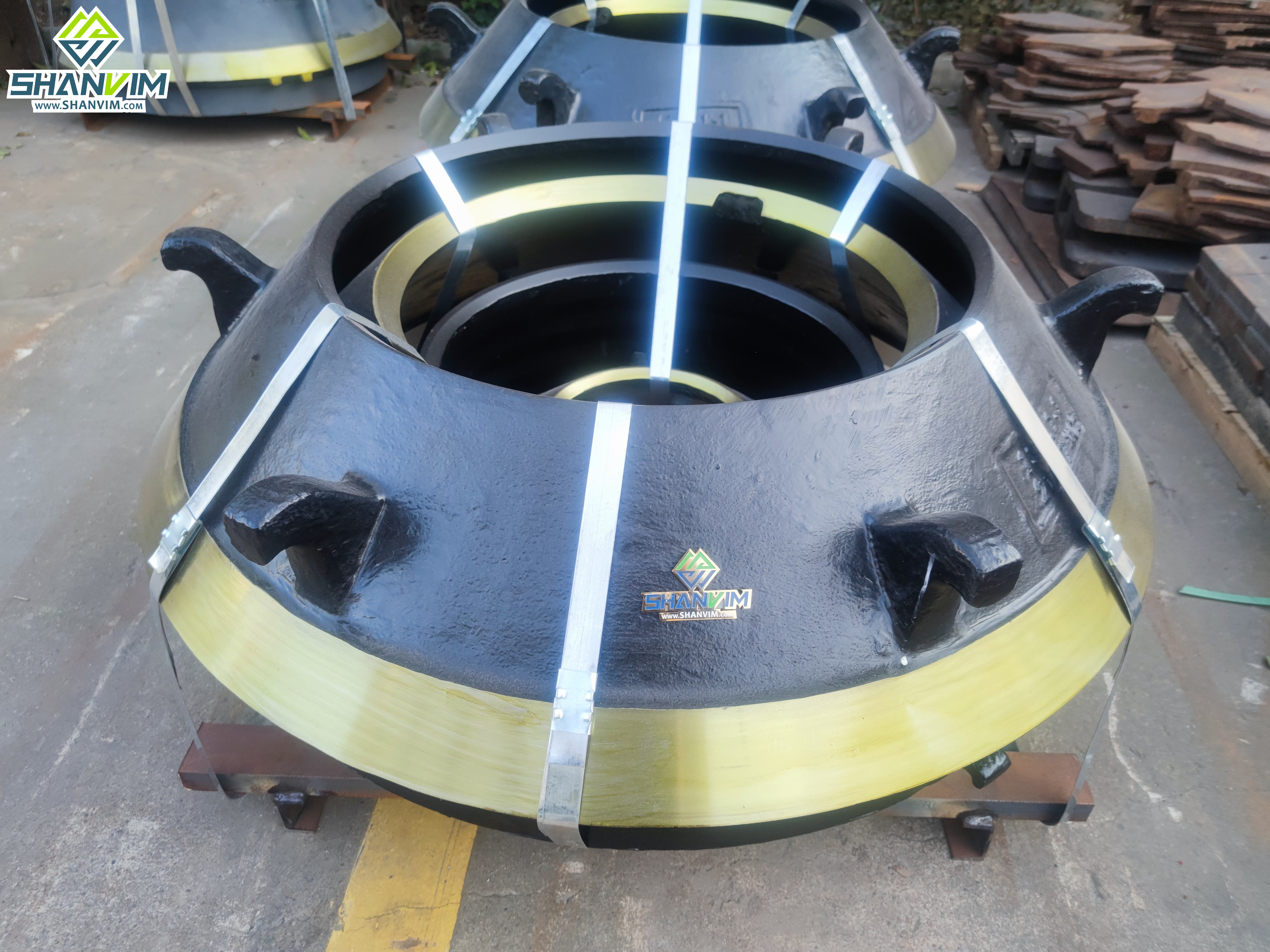

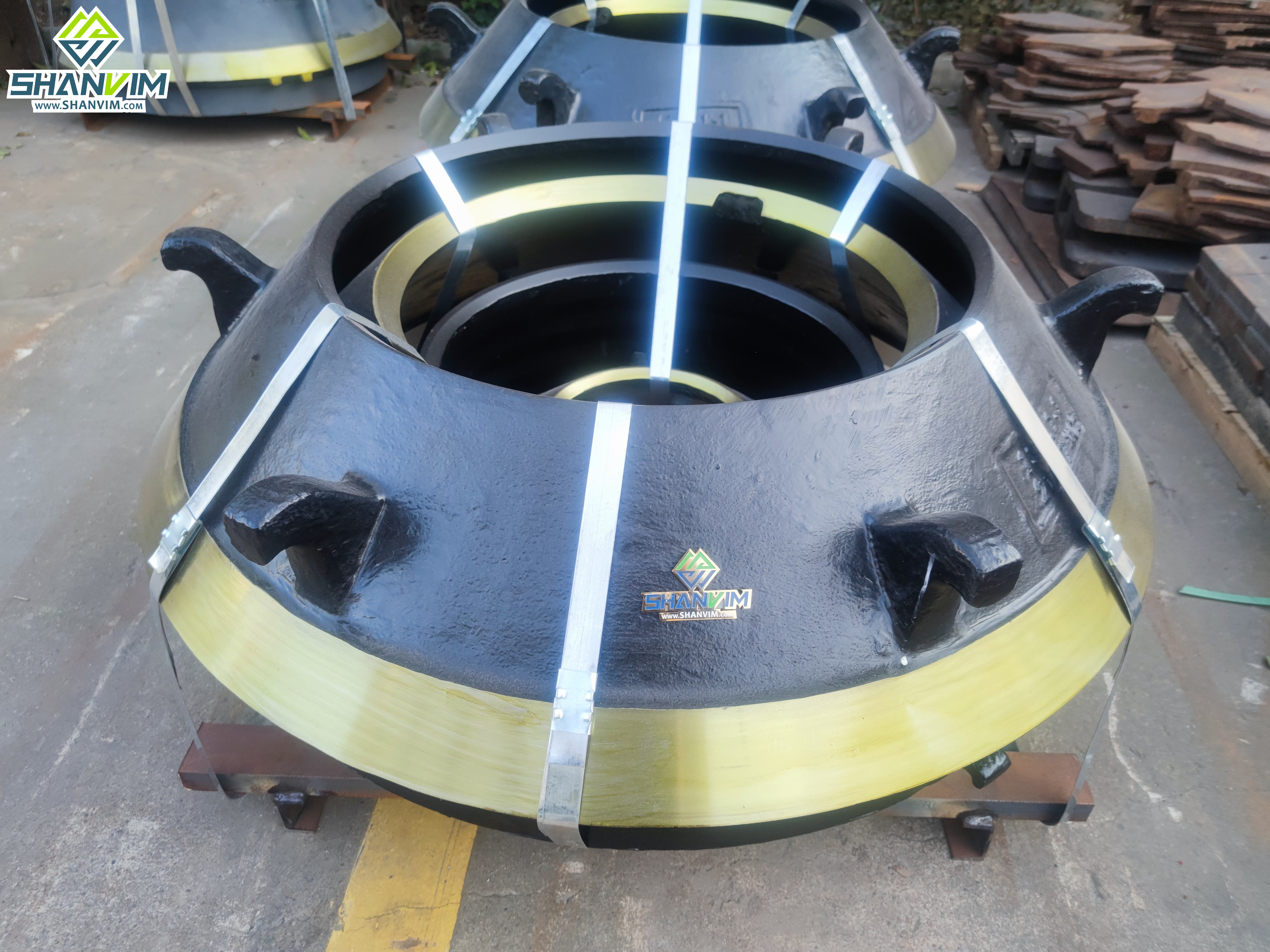

Shanvim Industry – What is the difference between Mantle and bowl liner

Mantle and bowl liner are the main parts that work together in the cone crusher to crush materials. The difference between Mantle and bowl liner is as follows: Mantle, one of the main components of a cone crusher, also known as the moving cone, is fixed on the cone body with a cone head. It is f...Read more -

Shanvim – how to improve the production capacity of the impact crusher?

Guide:The impact crusher is a kind of mining machinery. In the mine crushing production line, impact crusher is generally used for the second crushing operation. It is widely used in mine production due to its advantages of simple structure, low price, good crushed particle shape, being conduciv...Read more -

What are the advantages of hammer crushers? Can it crush granite?

To Hammer crushers are widely used in the building materials industry, highways, railways, metallurgy and other industries. It is a new type of crushing machine that uses a high-speed rotating hammer to impact materials to make them break along the natural cracks, layers and joint surfaces of the...Read more -

Shanvim – The Importance of the Blowbar – Impact Crusher

The impact crusher is mainly used in mining, railway, construction, highway construction, building materials, cement, chemical engineering and other sectors. The blowbar is an important part of impact crusher. When an impact crusher is working, blowbar impacts materials with the rotation of rotor...Read more -

What are the necessary equipment for the sand production line?

With the rapid growth of economic development and the acceleration of urbanization developing in recent years, the demand for sand and aggregates continues to increase. Therefore, the price of sand and aggregates is also rising. More people are attracted to invest in producing machine-made sand. ...Read more