News

-

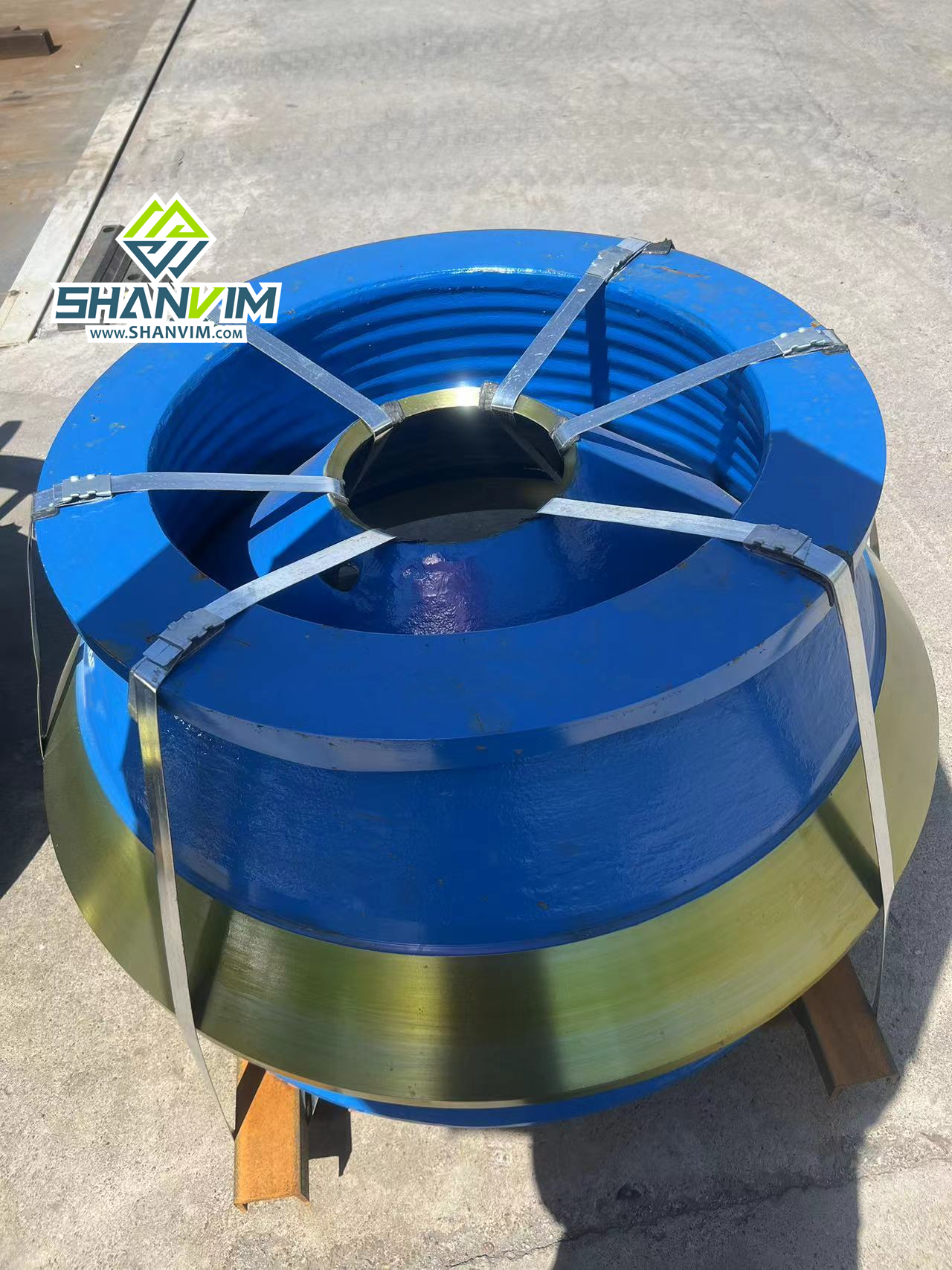

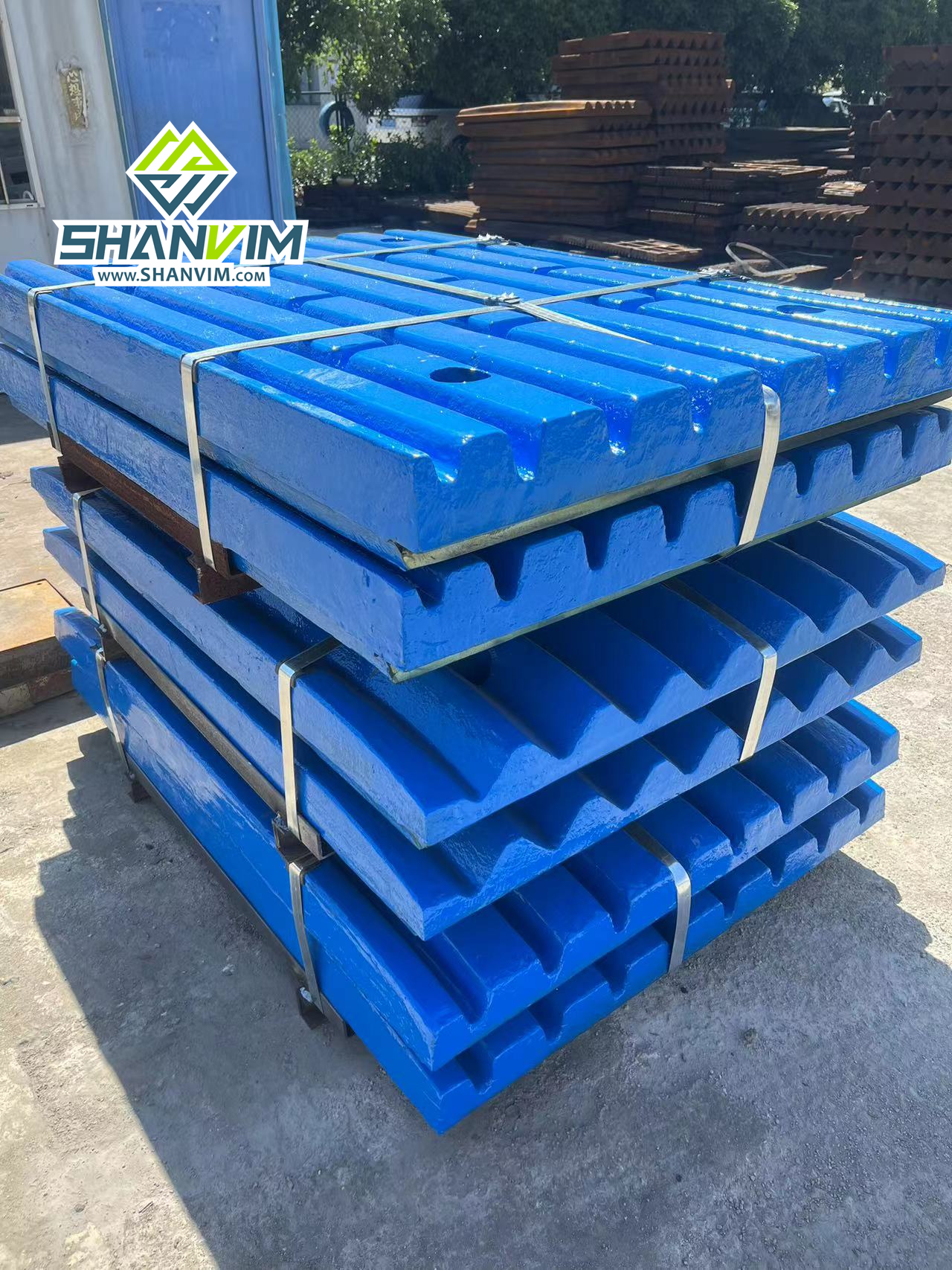

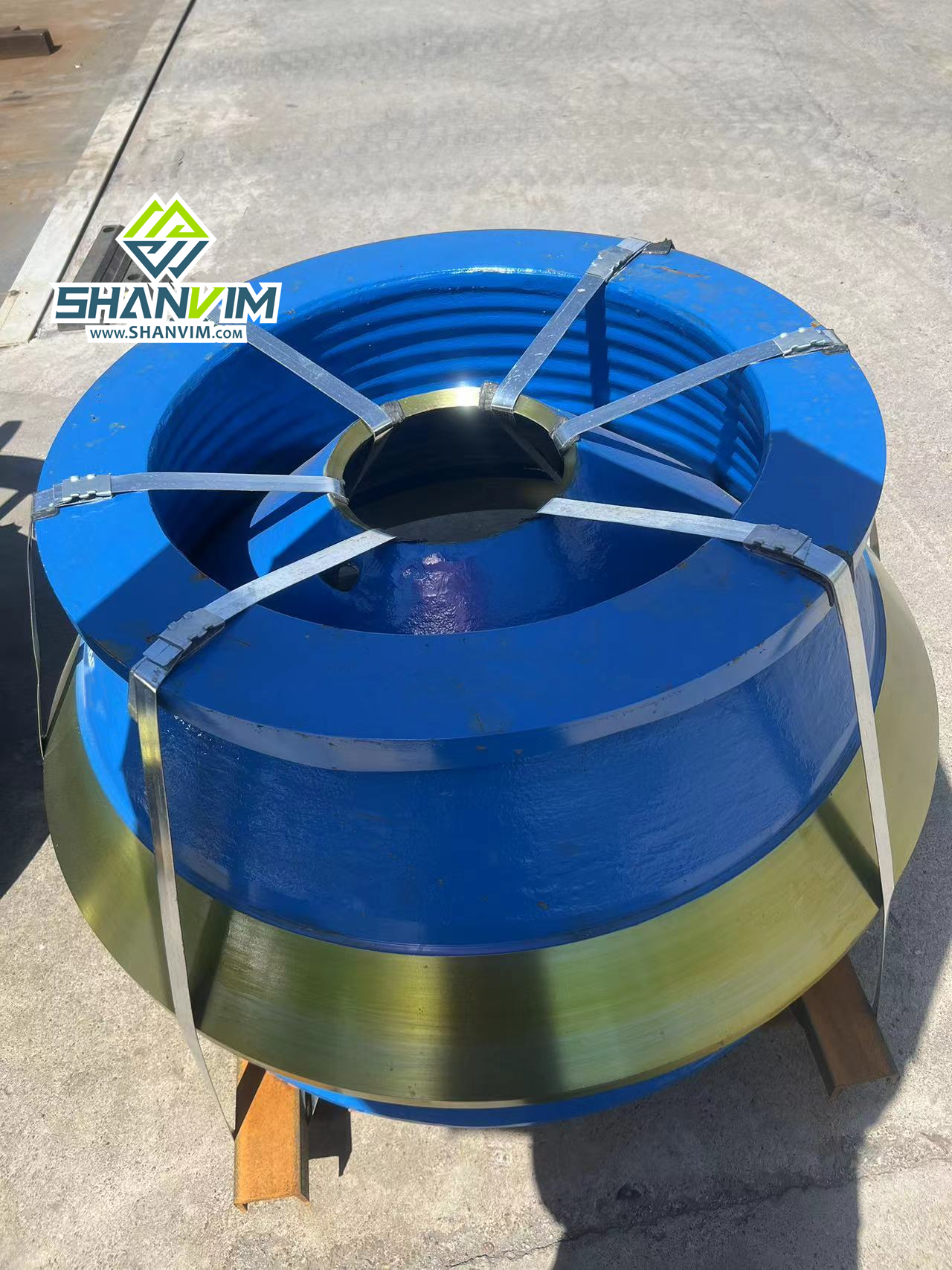

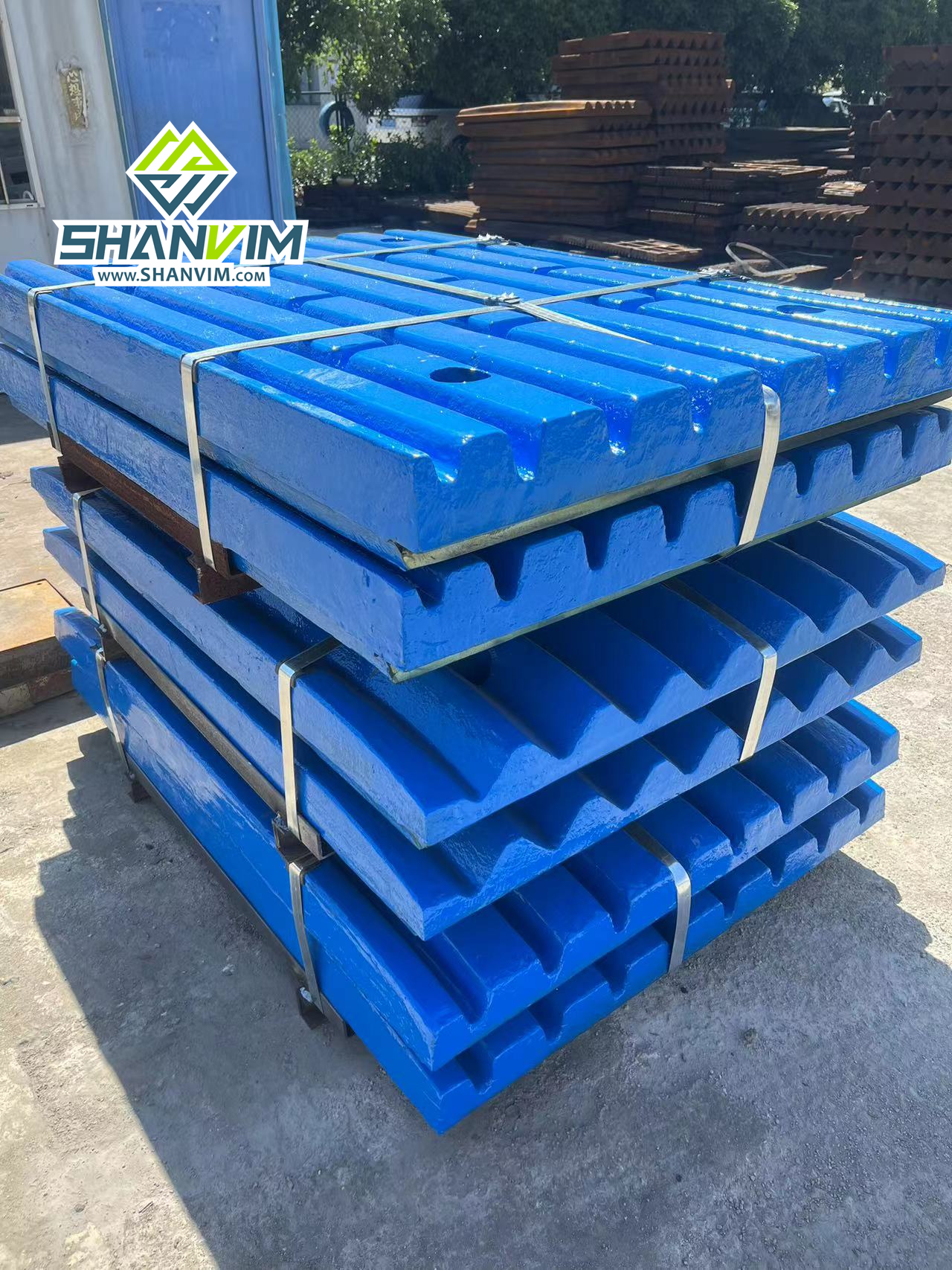

Shanvim Introduction How to replace the mantle and concave?

When replacing the mantle and concave of the cone crusher, the wear of the fixed cone, adjusting ring, locking thread, counterweight and counterweight guard must be checked. If the wear is serious, replace it with a new one, and then install the liner, which can reduce the time for secondary repl...Read more -

All You Need To Know About Cone Crushers

Cone crushers are one of the most useful and versatile pieces of crushing equipment available for quarries and mining operations.These machines often play an integral role in the delivery of aggregate products in the marketplace.Cone crushers are specialized pieces of equipment,with many manufact...Read more -

CRUSHING STAGES AND CRUSHER TYPES

There are different type crushers that achieve various objectives in material processing. Every application calls for a certain type crusher or a combination of multiple crushing stages to achieve a certain aggregate production goal. Primary Crushing:From Large to Medium A primary crusher provid...Read more -

WHY ARE MY IMPACT CRUSHER BLOW BARSBREAKING?

There are many reasons why your impact crusher blow bars are breaking on a regular basis.We have complied a list of the most common causes of blow bar failure and the solutions to those problems. 1.BLOW BAR NOT SEATING AGAINST ROTOR Possible Causes 1) The rotor is not straight or needs to be ...Read more -

The way you Feed your Small Rock Crusher Affects Your Bottom Line

Feeding a crusher needs a different approach.You can’t feed your small rock crusher like you would feed a dump truck (1)The smaller the rock crusher the smaller the shovel Small rock crushers are best fed with a excavator.Using a front-end loader is only recommended for rock crushers with a bigg...Read more -

What’s the best way to crush when the material is wet and has mud?

Rain can take the fun out of a crushing job Some people say that you are better off crushing beer cans than rock when it is raining,and your material is full of mud.Additionally,if you are not prepared for it, you will struggle to keep crushing and are forced to leave the convenience of your cab ...Read more -

Small Rock Crusher Feeding Tips for Novice Operators

Feeding a crusher correctly is as important as the crusher itself.If misused,you lose production and increase wear costs.The article helps you find the ideal setup for feeding your small rock crusher. Small Rock Crusher Feeder Types Typically,mobile rock crushers feature 3 types of feeders-a bel...Read more -

Crushed stone is an ideal material for road construction

Sandstone is a sedimentary rock consisting of sandy-sized cemented fragments.It is a formed mainly from ocean,beach and lake sedimentx and to a lesser extent froma sand dunes.It consists of small-grained minerals(quartz) cemented with siliceous,calcareous,clay,iron,gypsum,asphalt and other natura...Read more -

Which material is more suitable for impact crusher and hammer crusher?

Although impact crushers and hammer crushers are somewhat similar in terms of crushing principles, there are still certain differences in specific technical structures and working principles. 1. The difference in technical structure First of all, the impact crusher has a large crusher cavity and...Read more -

How to produce quality aggregates for construction?

Quality aggregates starts with material management. The raw material and material management are as important as your aggregate crushing process.If your feed material has low quality, your finished product will be of low quality as well.In addition, if you mixed good products with debris or have ...Read more -

Turn your concrete into cash with a compact crusher

High-quality aggregates for sale or use Maximize profits Cut tipping fees, and trucking costs. Produce a valuable aggregate product for use or sale. Increase flexibility Often it’s not enough to deconstruct an old farm and haul off debris. Add an additional service for your customers. Increase p...Read more -

Tips For Minimizing Wear

In order to protect your equipment that is being used,it is important to take measures to prevent wear and tear.There are a few things that be done to achieve this. The first tip is to make sure that the equipment is properly sized for the job.If it is too big or too small,it will put unn...Read more