PRODUCTS

MANGANESE WOPHUNZITSA BLOW BAR

Kufotokozera

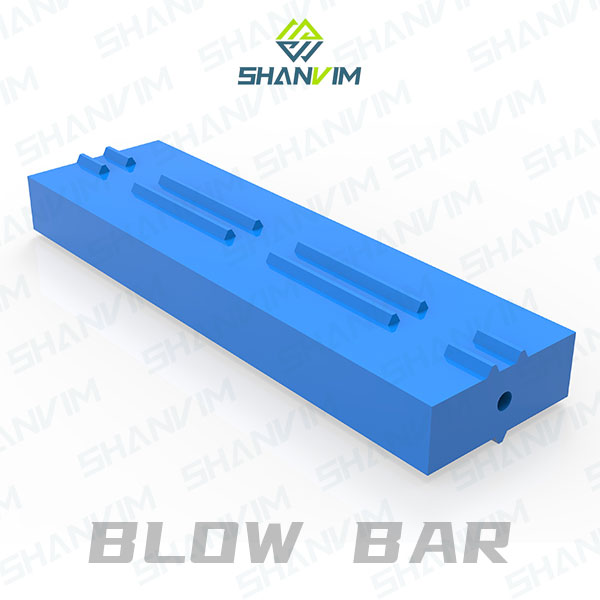

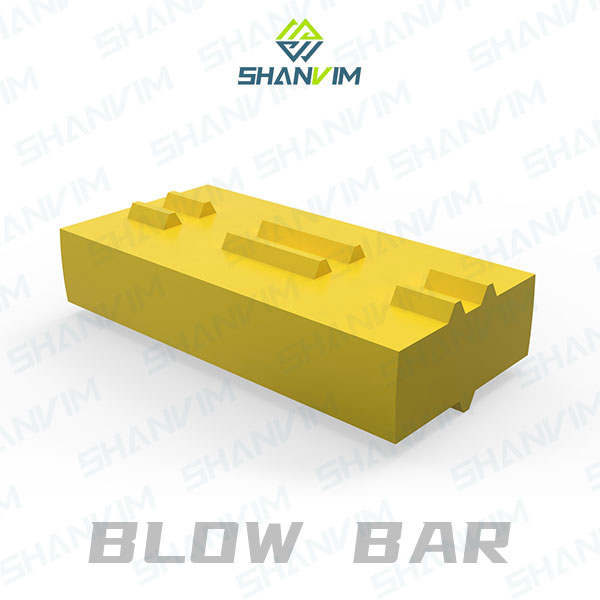

Mipiringidzo yowombandi zitsulo zokhuthala, nthawi zambiri zosakaniza za chrome, zomwe zimapangidwa ndi cholinga chophwasula bwino zinthu monga phula, konkire, miyala yamchere, ndi zina.

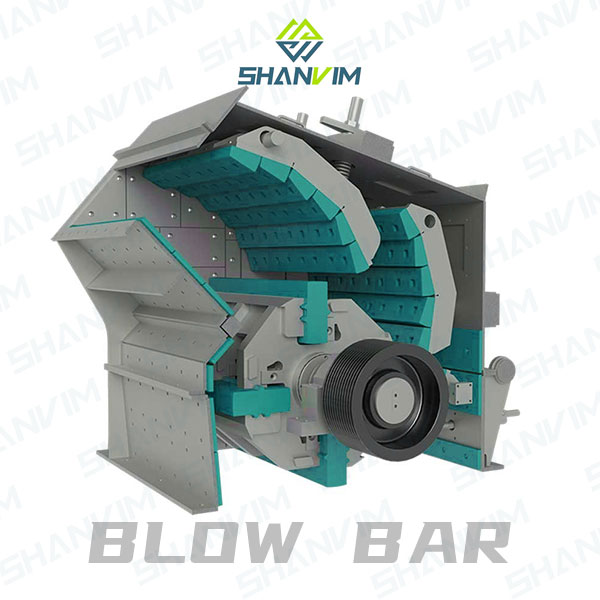

Chowombera chowomberandi gawo lofunika kwambiri pa nthawi yophwanyidwa ndihorizontal shaft impactor. Zida zazitsulo zowombera nthawi zambiri zimasankhidwa molingana ndi ntchito ya crusher.

Mukayikidwa muzopingasa zopingasa, mipiringidzo yowomba imayikidwa murotorndi kuzungulira mothamanga kwambiri, kupangitsa msonkhano wonse wa rotor ukuzungulira mobwerezabwereza kugunda zinthuzo. Panthawi imeneyi, aphulitsaimathyola zidazo mpaka zitakumana ndi kukula koyenera kuti zigwerekukhudza chipinda cha crusher.

Zida Zina Zosinthira Zenizeni - Mabala a Impact Crusher Blow Opangidwa Ndi SHANVIM

SHANVIM® imapereka mapangidwe osiyanasiyana ndikupanga mayankho osiyanasiyana owombera pamitundu yambiri ya OEM yopingasa yopingasa kuphatikiza: Hazemag, Mesto, Kleemann, Rockster, Rubble Master, Powerscreen, Striker, Keestrack, McClosky, Eagle, Tesab, Finlay ndi ena. . SHANVIM®"Njira Yeniyeni"mipiringidzo ya blower idapangidwa kuti iwonjezere moyo wa kuvala, kukupatsirani kusinthika koyenera kosinthika kwa othandizira anu, ndikuwonjezera mitengo yopangira pomwekuchepetsa mtengo pa toni.

Ma SHANVIM® Alternative Blow Bars Alipo Pa Ma Model Pansipa Akugwa

Nsagwada zonse zoyima komanso zosunthika zimatha kukhala zathyathyathya kapena malata. Nthawi zambiri, mbale za nsagwada zimapangidwa ndi chitsulo chokwera cha manganese chomwe chimavala kwambiri. Chitsulo chachikulu cha manganese chimatchedwansoHadfield manganese chitsulo, chitsulo chomwe manganese ake ndi okwera kwambiri ndipo ali nachoaustenitic katundu. Mambale oterowo si olimba kwambiri komanso amakhala odumphira komanso olimba akagwiritsidwa ntchito.

Timapereka mbale za nsagwada mu 13%, 18% ndi 22% magiredi a manganese okhala ndi chromium kuyambira 2% -3%. Onani pansipa tebulo lathu lapamwamba la nsagwada za manganese:

Metallurgy of the Blow Bars

SHANVIM crusher blower mipiringidzo imapezeka muzitsulo zosiyanasiyana kuti zikwaniritse zosowa zanu zapadera. Mitundu yambiri yazitsulo imaphatikizapo Manganese, Low Chrome, Medium Chrome, High Chrome, Martensitic ndi Composite Ceramic.

Monga momwe tawonetsera pachithunzichi, kuwonjezeka kwa chitsulo chokanizidwa ndi chitsulo (kuuma) nthawi zambiri kumatsagana ndi kuchepetsa kulimba (kutsutsa) kwa zinthuzo.

MANGANESE zitsulo

Kukana kuvala kwachitsulo cha manganese chokhala ndi mawonekedwe austenitic kumabwera chifukwa cha kuuma kwa ntchito. Zomwe zimakhudzidwa ndi kupanikizika zimabweretsa kuuma kwa dongosolo la austenitic pamtunda. Kulimba koyambirira kwachitsulo cha manganese ndi pafupifupi. 20 HRC. Mphamvu yamphamvu ndi pafupifupi. 250J/cm².

Pambuyo poumitsa ntchito, kuuma koyamba kumatha kufika pafupifupi. 50 HRC. Zozama zakuya, zomwe sizinali zowumitsidwa potero zimapereka kulimba kwakukulu kwachitsulo ichi. Kuzama ndi kuuma kwa malo olimba-ntchito kumadalira kugwiritsa ntchito ndi mtundu wa chitsulo cha manganese.

Chitsulo cha manganese chinali ndi mbiri yakale. Masiku ano, chitsulochi chimagwiritsidwa ntchito kwambiri pophwanya nsagwada, kuphwanya ma cones ndi kuphwanya zipolopolo (zovala & mbale zomangira). Mu chophwanyira, ndi bwino kugwiritsa ntchito manganese kuwomba mipiringidzo pamene kuphwanya zochepa abrasive ndi lalikulu kwambiri chakudya chakudya (monga laimu).

CHROME zitsulo

Ndi chitsulo cha chrome, kaboniyo imamangirizidwa mwanjira ya chromium carbide. Kukaniza kuvala kwa chitsulo cha chrome kumachokera ku ma carbides olimba a matrix olimba, momwe kusuntha kumalepheretsedwa ndi zowonongeka, zomwe zimapereka mphamvu zambiri koma nthawi yomweyo zimakhala zolimba.

Kuti zinthu zisawonongeke, zitsulo zowombera ziyenera kutenthedwa ndi kutentha. Izi ziyenera kuzindikirika kuti kutentha ndi nthawi ya annealing zimatsatiridwa ndendende. Chitsulo cha Chrome nthawi zambiri chimakhala cholimba cha 60 mpaka 64 HRC komanso mphamvu yochepa kwambiri ya 10 J/cm².

Pofuna kupewa kusweka kwa mipiringidzo yazitsulo za chrome, sipangakhale zinthu zosasweka muzakudya.

SHANVIM Chorme Blow Bars Elements

| High Chrome Casting Material Chemical Composition | |||||||||

| Kodi Elem | Cr | C | Na | Cu | Mn | Si | Na | P | Mtengo wa HRC |

| KmTBCr4Mo | 3.5-4.5 | 2.5-3.5 | / | / | 0.5-1.0 | 0.5-1.0 | / | ≤0.15 | ≥55 |

| KmTBCr9Ni5Si2 | 8.0-1.0 | 2.5-3.6 | 4.5-6.5 | 4.5-6.5 | 0.3-0.8 | 1.5-2.2 | 4.5-6.5 | / | ≥58 |

| KmTBCr15Mo | 13-18 | 2.8-3.5 | 0-1.0 | 0-1.0 | 0.5-1.0 | ≤1.0 | 0-1.0 | ≤0.16 | ≥58 |

| KmTBCr20Mo | 18-23 | 2.0-3.3 | ≤2.5 | ≤1.2 | ≤2.0 | ≤1.2 | ≤2.5 | ≤0.16 | ≥60 |

| KmTBCr26 | 23-30 | 2.3-3.3 | ≤2.5 | ≤2.0 | ≤1.0 | ≤1.2 | ≤2.5 | ≤0.16 | ≥60 |

Malingaliro a kampani MARTENSITIC zitsulo

Martensite ndi mtundu wachitsulo wodzaza ndi mpweya womwe umapangidwa ndi kuzizira kofulumira. Ndi kokha mu chithandizo cha kutentha chotsatira chomwe carbon imachotsedwa ku martensite, yomwe imapangitsa mphamvu ndi kuvala katundu. Kulimba kwachitsulochi kumakhala pakati pa 44 mpaka 57 HRC ndi mphamvu yamphamvu pakati pa 100 ndi 300 J/cm².

Choncho, ponena za kuuma ndi kulimba, zitsulo za martensitic zimakhala pakati pa chitsulo cha manganese ndi chitsulo cha chrome. Amagwiritsidwa ntchito ngati chiwongola dzanja chili chochepa kwambiri kuti chiwumitse chitsulo cha manganese, ndi / kapena kukana kwabwino kumafunika komanso kukana kupsinjika.

METAL MATRIX NDI COMPOSITE ZA CERAMIC

Metal Matrix Composites, kuphatikiza kukana kwakukulu kwa matrix achitsulo ndi zoumba zolimba kwambiri. Porous preforms zopangidwa ndi ceramic particles amapangidwa pochita izi. Chitsulo chosungunuka chachitsulo chimalowera mu netiweki ya ceramic porous. Zomwe zimachitikira komanso chidziwitso ndizomwe zimapangidwira momwe zida ziwiri zosiyana - zitsulo zokhala ndi 7.85 g/cm³ ndi ceramic ndi makulidwe a 1-3 g/cm³ - zimaphatikizidwa ndipo pali kulowetsedwa bwino.

Kuphatikiza uku kumapangitsa kuti mipiringidzo yowombayo ikhale yosagwira ntchito koma nthawi yomweyo imakhala yosagwira. Ndi mipiringidzo yowombera yopangidwa ndi zophatikiza kuchokera kumunda wa ceramics, moyo wautumiki womwe umakhala wotalika katatu mpaka kasanu ngati chitsulo cha martensitic chingapezeke.