-

JAW PLATE FOR JAW CRUSHER

SHANVIM provides jaw liners made of manganese steel, which is suitable for various jaw crushers worldwide. Provide parts and technical support for the mining, aggregate, and recycling industry aftermarket. -

BI-METAL COMPOSITE JAW PLATE

In view of the working principle of jaw crusher and its practical application status, a double-liquid bimetallic composite casting jaw was developed. The working face is made of alloy steel with high wear resistance. The lining is made of cast steel with good impact toughness, Give full play to the characteristics of various materials. At the same time, the special pouring system and casting process ensure the uniform and complete interface of the composite material and optimize the service performance of the jaw plate.

-

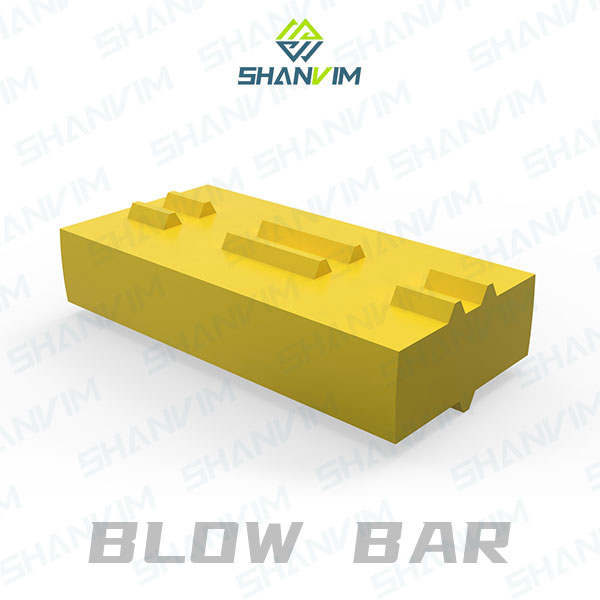

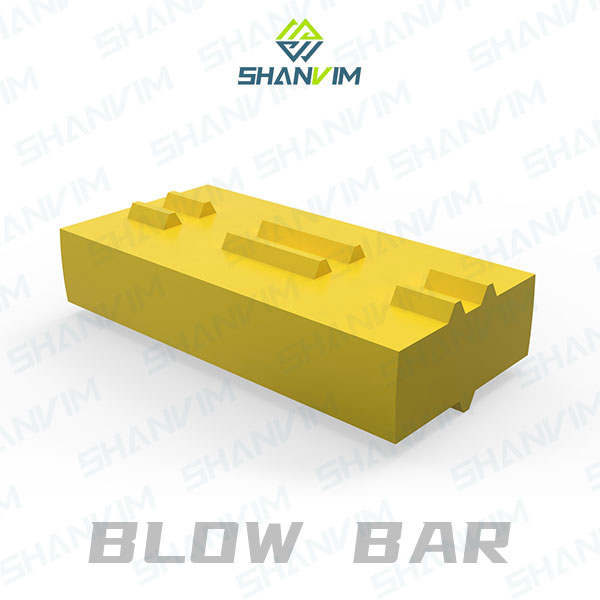

HIGH WEAR-RESISTANCE BLOW BAR

Shanvim provide Premium Replacement Parts for Metso and Sandvik Crushers. When it comes to Replacement Metso and Sandvik Crusher Parts, Shanvim has been OEM blow bar, abrasion resistance, long service time, fully-guaranteed . -

BLOW BAR-CASTING METAL

The main wearing parts of Impact Crusher are blow bars and impact plates, with special heat-treatment, the hardness of our blow bar can reach to HRC58~HRC63. The product mainly uses high manganese steel material, for example Mn14Cr2, Mn18Cr2, Mn22Cr2 and so on.

SHANVIM’s blow bars and impact plates are widely used on mining, construction, chemical, cement and metallurgical industry. Our impact parts have a service life 50~100% longer than those made of traditional high chromium iron.

-

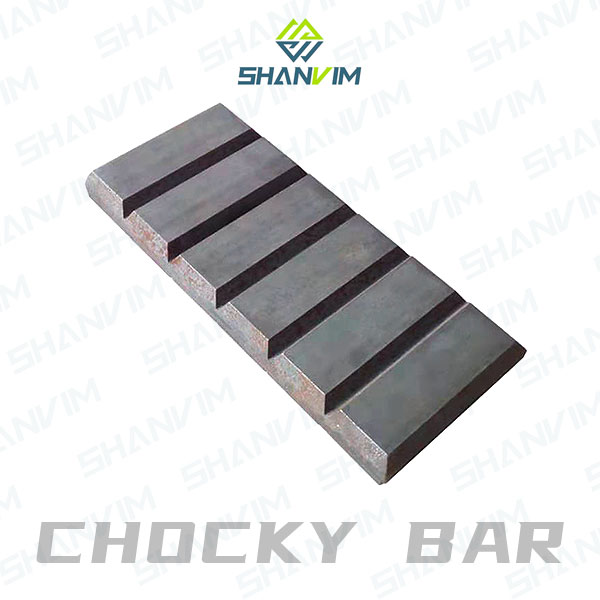

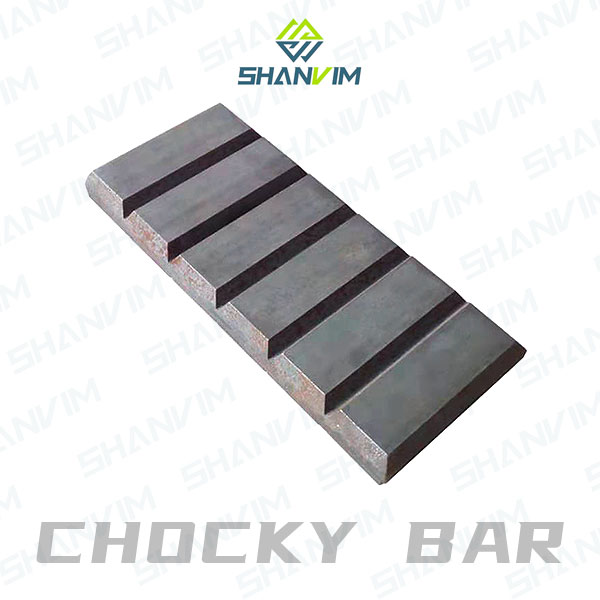

CHOCKY BARS WITH METAL CERAMIC

weldability wear-resistant bar/liner (Chocky Bar) is one of the highly alloyed chromium white iron wear parts and

looks like chocolate. the composite layer hardness is harder than high Cr material 3-4 times,The mild steel backing

plate has very good welding performance while bearing high impact.

-

HIGH CHROME BLOW BAR

The high chrome blow bar especially suit for hard rock crushing with high efficiency and energy saving, the discharge material size is smaller, and shape more equal. We can special produce according to requirement. (OEM produce)

-

COPPER BUSHING-CYLINDER CONE CRUSHER PARTS

Bushings & Liners are an indispensable part of cone crushers. They are usually used to protect eccentric shafts, sockets, and countershafts from wear caused by high-speed rotation. Cone crusher bushings and liners are generally made of bronze and alloy steel, and they often need to be filled with lubricant on the surface or inner wall during use.

Improper installation or use of poor quality cone crusher bushings & liners will greatly shorten the service life of the key parts due to the large amount of heat generated during operation. Therefore, choosing high-quality cone crusher bushings & liners is the best way to extend the life of the machine and reduce maintenance costs. -

HAMMER WITH WEARABLE STEEL

Our hammers are made in austenitic manganese steel and proprietary low-alloy steel. SHANVIM also makes a differentially-hardened, low alloy steel hammer that is extremely hard on the bottom and possesses a softer material around the pin to keep the pin from wearing out. In essence, we are able to right-size the metallurgy of the casting to the particular application, resulting in the most wear-resistant part available. -

GRATES FOR MINERAL PROCESSING

Grates(single or double beam grate) that fit – and handle the uncertainties of shredding. -

CHOCKY BAR-EASY TO USE

1.Product: Wearing spare parts for excavator buckets.

2.Material: High Manganese steel and Carbon steel.

3.OEM is welcome.

4.Certification: ISO9001.

This product is very easy to use. It's easy to be cut and welded on curved surface without pre-heat or after heat

treatment. It's easy to be transported as it's very small. It's an ideal small area repairing wear part without too much

welding time. We have a complete range of specification and are able to customize and develop according to

customer's requirement. Comparing with normal High manganese steel wear resistant casting wear parts, this

product's service life is 4-8 times longer. -

CHOCKY BAR-EXCAVATOR PARTS

SHANVIM chocky bars&wearing button are easy to cut and form onto inside and outside contoured surfaces. Users can calculate their own lay-outs and patterns depending on the area and shape of the parts that they want to protect. The notches in SHANVIM chocky bars&wearing button casting and/or backing plate assist in cutting them to size or bending them to shape to suit the application. -

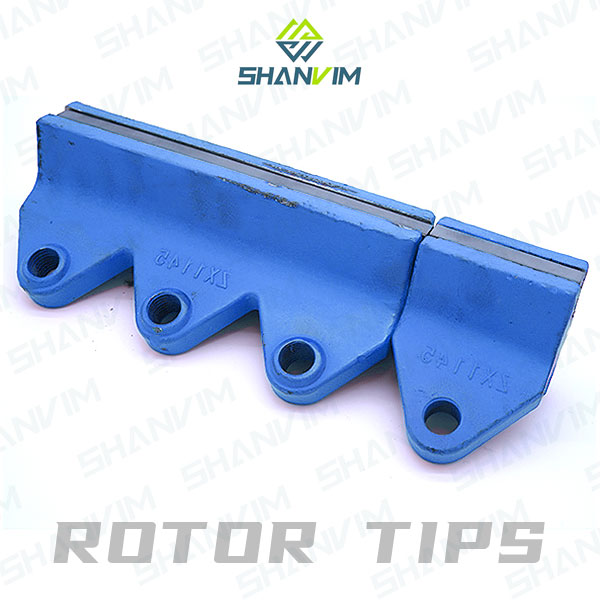

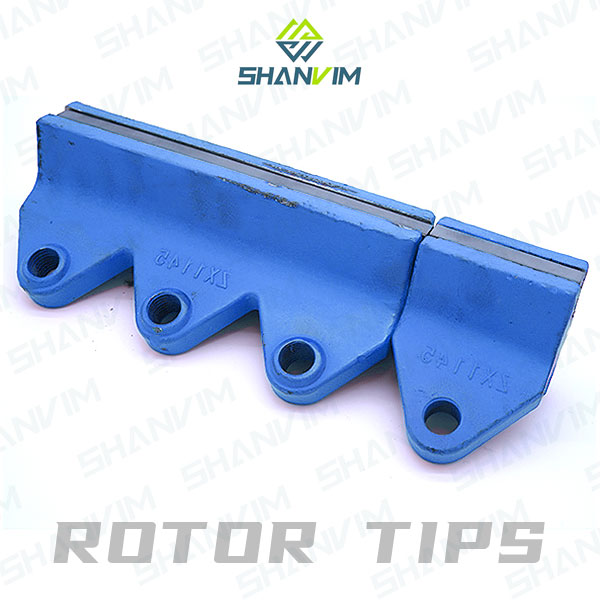

TIP AND BACK-UP TIP

The Rotor tips are the last thing to touch the feed material as it exits the rotor. They have a Tungsten insert that improves wear life. We often use the life of the tips as a reference point for the other rotor wear parts.

The back-up tip is designed to protect the rotor if and when a rotor tip gets broken or worn out. When this happens the Tungsten insert in the rotor tip has split and is now letting feed material run against the Tungsten insert of the back-up tip.The back-up tip has a small Tungsten insert in it that will last for about 8 -10 hours of wear in normal operation. If this backup is broken again, or it wears out then the feed material can seriously damage the rotor due to abrasion.