PRODUCTS

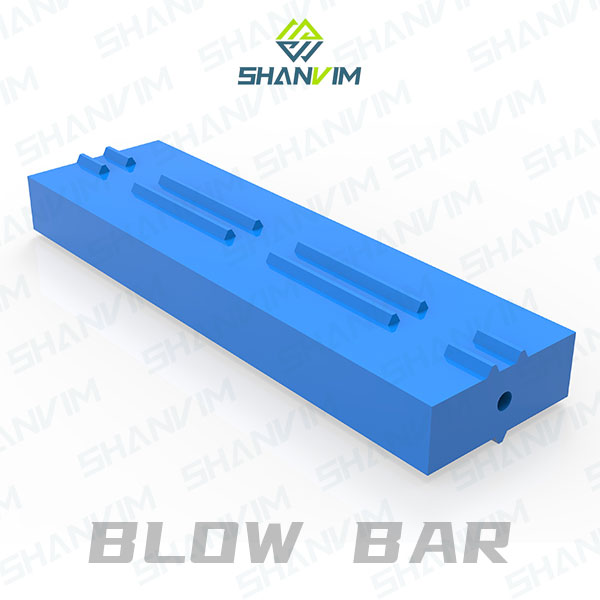

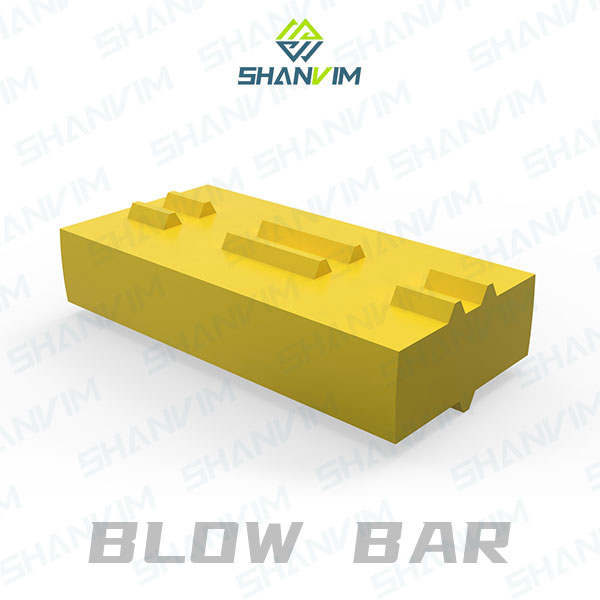

HIGH MANGANESE BLOW BAR

Tsanangudzo

Bvudzira mbariromasimbi akakora esimbi, anowanzo musanganiswa wechrome, anogadzirwa nechinangwa chekupwanya zvinhu zvakaita seasphalt, kongiri, limestone, nezvimwe.

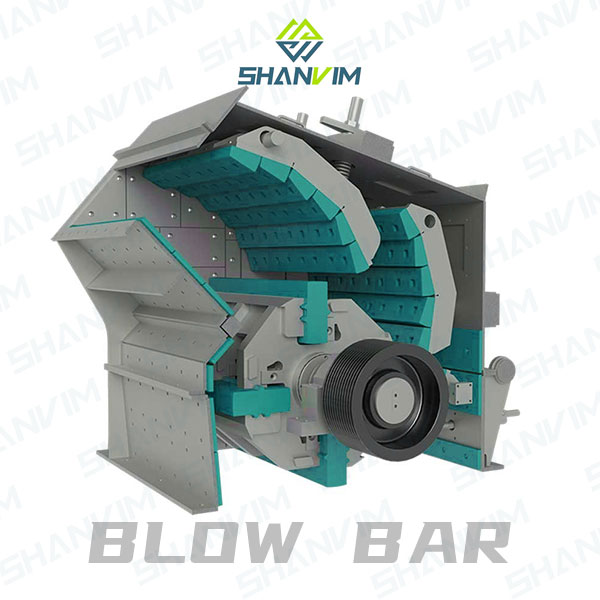

Blow barchikamu chakakosha panguva yekupwanya maitiro nehorizontal shaft impactor. Zvishandiso zvemabhawa ekubhowa zvinowanzosarudzwa zvinoenderana nebasa reiyo impact crusher.

Kana yaiswa mune yakachinjika kukanganisa macrusher, mabheti ekuputira anoiswa mukatirotoruye yakatenderedzwa nekumhanya kukuru, ichiita kuti gungano rose rotor ritenderere kakawanda richirova zvinhu. Munguva iyi nzira, theblow barinotsemura zvinhu kusvika zvasangana nehukuru hwakakodzera kuti hubude kuburikidza nekukanganisa crusher chamber.

Genuine Alternative Spare Parts - Impact Crusher Blow Bars Yakagadzirwa naSHANVIM

SHANVIM® inopa madhizaini akasiyana uye inogadzira akasiyana magadziriso ebhero yemhando yakakura yeOEM yakachinjika kukanganisa crusher brand inosanganisira: Hazemag, Mesto, Kleemann, Rockster, Rubble Master, Powerscreen, Striker, Keestrack, McClosky, Gondo, Tesab, Finlay nevamwe. . SHANVIM®"Genuine Alternative"mabheti ekuputira akagadzirirwa kuwedzera hupenyu hwekupfeka, kupa yakakwana inochinjika yakakodzera kune yako impactor, uye kuwedzera mitengo yekugadzira panguva.kuderera kwemitengo-pa-tani.

SHANVIM® Alternative Blow Bars Anowanikwa Kune Pazasi Models Collapse

Dzese dzakamira uye dzinofambiswa shaya dzinofa dzinogona kuve dzakati sandarara pamusoro kana kuti marara. Kazhinji, mahwendefa eshaya anogadzirwa nesimbi yakakwira manganese inova ndiyo inonyanya kupfeka zvinhu. High manganese simbi inozivikanwawo seHadfield manganese simbi, simbi ine manganese yakakwira zvakanyanya uye ineaustenitic properties. Mahwendefa akadaro haana kungonyanya kuomarara chete asi zvakare ane ductile uye anoshanda-akaoma nekushandisa.

Isu tinopa mahwendefa eshaya mu13%, 18% uye 22% magiredhi emanganese ane chromium kubva pa2% -3%. Tarisa pazasi tafura yedu yakakwira manganese jaw die properties:

Metallurgy yeBlow Bars

SHANVIM crusher blow mabara anowanikwa mune akasiyana simbi simbi kuti agadzirise zvakasarudzika zvekupwanya zvaunoda. Mhando dzesimbi dzinosanganisira Manganese, Low Chrome, Medium Chrome, High Chrome, Martensitic uye Composite Ceramic.

Sezvinoratidzwa mumufananidzo, kuwedzera kwesimbi yekupfeka kusagadzikana (kuoma) kunowanzoperekedzwa nekuderera kwekuoma (impact resistance) yezvinhu.

MANGANESE STEEL

Kupfeka kuramba kwesimbi manganese ine austenitic chimiro kunokonzerwa nechiitiko chekuoma kwebasa. Iko kukanganisa uye kudzvinyirira mutoro kunoguma nekuoma kwechimiro che austenitic pamusoro. Iko kuoma kwekutanga kwesimbi manganese ndeye approx. 20 HRC. Iko simba rekuita rinenge. 250J/cm².

Mushure mekuoma kwebasa, kuoma kwekutanga kunogona kusvika kusvika kusvika approx. 50 HRC. Iwo akadzama-seti, asati akaomeswa akaturikidzana nokudaro anopa kusimba kukuru kwesimbi iyi. Kudzika uye kuoma kwenzvimbo yekushanda-yakaoma kunoenderana nekushandiswa uye rudzi rwesimbi yemanganese.

Manganese simbi ine nhoroondo refu. Nhasi, simbi iyi inonyanya kushandiswa pakupwanya shaya, kupwanya makoni uye kupwanya magomba (mantles & ndiro liner). Mune inorovera crusher, zvinongokurudzirwa kushandisa manganese blow bars paunenge uchipwanya zvishoma abrasive uye yakakura kwazvo feed material (eg limestone).

CHROME simbi

Ne chrome simbi, kabhoni inosungirirwa mumakemikari nenzira yechromium carbide. Kupfeka kupikisa kwe chrome simbi kunobva pane idzi dzakaoma carbides dzematrix akaoma, umo kufamba kunodziviswa nekugadzirisa, izvo zvinopa hukuru hwesimba asi panguva imwe chete hushoma kuoma.

Kuti udzivise zvinhu kubva pakuita brittle, mbariro dzinoputika dzinofanira kupiswa. Izvo zvinofanirwa kucherechedzwa kuti tembiricha uye annealing nguva paramita inotevedzwa chaizvo. Chrome simbi inowanzoita kuoma kwe60 kusvika 64 HRC uye yakaderera zvakanyanya simba re10 J/cm².

Kuti udzivise kuputsika kwe chrome simbi inovhuvhuta mabara, panogona kunge pasina chero chinhu chisingaputsike mumidziyo yekudyisa.

SHANVIM Chorme Blow Bars Elements

| Yakakwira Chrome Inokanda Material Kemikari Kuumbwa | |||||||||

| Code Elem | Cr | C | Na | Cu | Mn | Si | Na | P | HRC |

| KmTBCr4Mo | 3.5-4.5 | 2.5-3.5 | / | / | 0.5-1.0 | 0.5-1.0 | / | ≤0.15 | ≥55 |

| KmTBCr9Ni5Si2 | 8.0-1.0 | 2.5-3.6 | 4.5-6.5 | 4.5-6.5 | 0.3-0.8 | 1.5-2.2 | 4.5-6.5 | / | ≥58 |

| KmTBCr15Mo | 13-18 | 2.8-3.5 | 0-1.0 | 0-1.0 | 0.5-1.0 | ≤1.0 | 0-1.0 | ≤0.16 | ≥58 |

| KmTBCr20Mo | 18-23 | 2.0-3.3 | ≤2.5 | ≤1.2 | ≤2.0 | ≤1.2 | ≤2.5 | ≤0.16 | ≥60 |

| KmTBCr26 | 23-30 | 2.3-3.3 | ≤2.5 | ≤2.0 | ≤1.0 | ≤1.2 | ≤2.5 | ≤0.16 | ≥60 |

MARTENSITIC STEEL

Martensite imhando yesimbi yakazara-kabhoni iyo inogadzirwa nekukurumidza kutonhora-kudzima. Izvo chete mune inotevera kupisa kurapwa iyo kabhoni inobviswa kubva martensite, iyo inovandudza simba uye kupfeka zvinhu. Kuoma kwesimbi iyi kunotangira pa44 kusvika ku57 HRC uye simba rekuita riri pakati pe100 ne300 J/cm².

Nokudaro, maererano nekuoma uye kuoma, martensitic steels ari pakati pemanganese simbi uye chrome simbi. Iwo anoshandiswa kana mutoro wekukanganisa uri mudiki zvakanyanya kuomesa manganese simbi, uye / kana yakanaka kupfeka kuramba inodiwa pamwe chete nekunaka kukanganisa kusagadzikana.

METAL MATRIX NE CERAMIC COMPOSITES

Metal Matrix Composites, sanganisa kupikisa kwakanyanya kwesimbi matrix ine yakanyanyisa kuoma ceramics. Porous preforms yakagadzirwa neceramic particles inogadzirwa mukuita. Iyo simbi yakanyungudutswa yakawanda inopinda mukati me porous ceramic network. Chiitiko uye ruzivo rwakanyanya kune maitiro ekukanda umo zvinhu zviviri zvakasiyana - simbi ine hutema hwe7.85 g/cm³ uye ceramic ine ukobvu hwe1-3 g/cm³ - inosanganiswa uye pane kunyatsopindwa.

Uku kusanganiswa kunoita kuti mabara ekuridza akanyanya kupfeka-kupokana asi panguva imwe chete zvakanyanya kukanganisa-resistant. Nekubhowa mabhawa akagadzirwa nemacomposites kubva kumunda weceramics, hupenyu hwesevhisi hwakapetwa katatu kusvika kashanu kureba sehuya hwemartensitic simbi hunogona kuwanikwa.