Alaabooyinka

Alaabta Shiineeska ah ee Shiineeska Sare ee Manganese Birta Daanka ee Daanka Metso

Shirkadeena tan iyo markii la aasaasay, sida caadiga ah waxay tixgelisaa tayada ugu sareysa sida nolosha shirkadda, waxay si joogto ah u horumarisaa tignoolajiyada jiilka, wanaajisaa badeecada aad u wanaagsan oo ku celcelinaysa xoojinta hay'adda guud ee maaraynta tayada wanaagsan, iyadoo la raacayo heerka heerka qaran ee ISO 9001: 2000 ee Shiinaha Alaabta ShiinahaBirta Manganese SareDaanka daanka ee Metso Daanka Crusher, Waxaan hadda haynaa alaab aad u weyn oo lagu fulinayo wicitaannada iyo baahiyaha macaamiisheena.

Shirkadeena tan iyo markii la aasaasay, sida caadiga ah waxay tixgelisaa tayada ugu sareysa sida nolosha shirkadda, waxay si joogto ah u horumarisaa tignoolajiyada jiilka, wanaajisaa badeecada aad u wanaagsan oo soo noqnoqota xoojinta hay'adda guud ee maaraynta tayada wanaagsan, iyadoo la raacayo heerka qaran ee ISO 9001: 2000Shiinaha Daanka Daanka, Birta Manganese SareWaxaan leenahay in ka badan 10 sano oo waayo-aragnimo ah dhoofinta iyo baayacmushtarkayadu waxay sahamiyeen in ka badan 30 waddan oo ereyga ah. Had iyo jeer waxaanu marka hore qabanaa macmiilka mabda'a adeega, tayada marka hore maskaxdeena, waxaanu ku adagnahay tayada alaabta. Ku soo dhawoow booqashadaada!

Sharaxaada

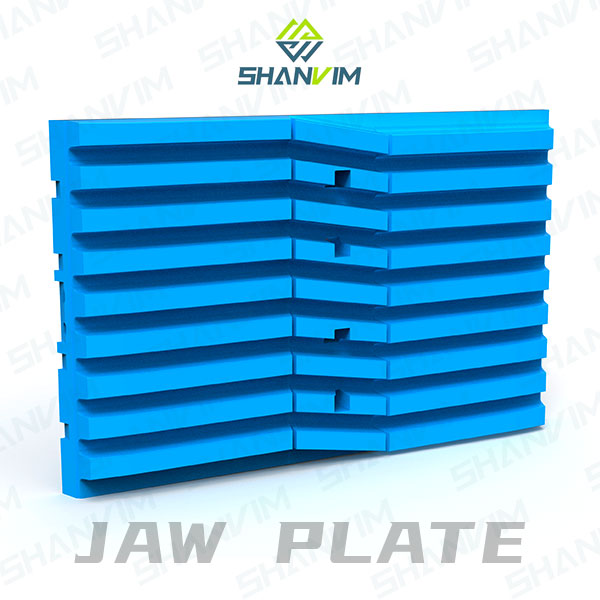

Saxanka daankaorDaanka wuu Dhintaywaa kuwa ugu badan ee la beddeloxidho qaybo ka mid ah burburiyaha daanka, si tayada eedaanka dhintawaa mid ka mid ah qodobbada ugu muhiimsan ee go'aamiya waxtarka burburinta iyo waqtiga hawlgalka.

Qayb ka mid ahsaxannada daankawaxay ka kooban yihiindhaqaaqi karo( daan lulid) iyosaxan daanka go'an(daanka taagan). Cadaadiska walxaha ku socda burburinta daanka burburinta waxa la gaadhaa markadaanka dhaqaaqi karo dhimanku cadaadiya feed ka dhanka ahdaanka go'an dhiman. Dhagaxu waxa uu ku sii jiraa daanka mishiinka wax burburinaya ilaa uu ka yar yahay in uu dhex maro farqiga u socda xagga hoose ee daanka.

① Waxaan bixinaa noocyo kala duwan oo muuqaallo ilig ah iyo qaababka dusha sare;

② Waxaan bixinaa qalab kala duwan oo daanka dhinta;

③ Waxaan soo saara alaab badan oo u adkaysata xidhashada;

④ Waxaan kordhineynaa nolosha adeegga daanka ayaa dhinta;

⑤ Sagxadaha ku habboon ee dhammaan daamankeena waa mashiinka la dhammeeyey si loo hubiyo ku habboonaanta ugu fiican;

⑥ Waxaan bixinaa qiimo badan oo tartan ah.

SHANVIM® waxay soo saartaa, kaydinta iyo sahayda"Beddel dhab ah"saxannada daanka oo si buuxda u ballaaran oo OEM daanka burburinaya oo ay ku jiraan laakiin aan ku xaddidnayn: Metso®, Sandvik®, Extec®, Telsmith®, Terex®, Powerscreen®, Kleemann®, Komatso®, Kemco®, Finlay® iyo Fintec®.

Ogaysiis:Jadwalka soo socda kuma jiraan dhammaan OEM taarikada daanka la beddeli karo ee aan soo saari karno. Haddii aad u baahan tahay qalabyada noocyada kale, ama aad ogaato lambarka taxanaha OEM ee saxanka daanka ee aad raadineyso inaad beddesho, ama aad ku siin karto sawirka taarikada daanka oo aad u baahan tahay inaad habeyso, fadlan xor u noqo inaadnala soo xidhiidhemail ahaan ama wac.

SHANVIM® Taargo Daanka Beddelka ah Oo Loo Heli Karo Noocyada Hoose & Qaababka Burburka

| Noocyada & Qaababka | ||||||

| METSO Nordberg C Taxanaha | METSO Lokotrack LT Taxanaha | Taxanaha SANDVIK CJ | SANDVIK CM Taxanaha | SANDVIK JM Taxanaha | Taxanaha SANDVIK UJ | SANDVIK EXTEC & FINTEC |

| C106 | LT96 | CJ815 | CM1208F | JM1107 | UJ310 | C-10 |

| KLEEMANN | KOMATSU | TELSMITH | TEREX POWERSCREEN | TEREX FINLAY | TEREX Cedarapids | KEMCO |

| MC100 R EVO | BR380JG | H2238 | METROTRAK | J-960 | JC2236 | F3 |

Dhimashada daanka taagan iyo kuwa dhaqaaqi karo labaduba waxay noqon karaan kuwo fidsan ama jiingado. Guud ahaan, taarikada daanka waxay ka samaysan yihiin birta manganese sare taas oo ah qalabka ugu badan ee xidhashada. Birta manganese sare waxa kale oo loo yaqaanaaHadfield manganese birta, Bir ka kooban manganese-ku aad u sarreeyo oo lehhantida austenitic. Taarikada noocaan oo kale ah kaliya ma aha kuwo aad u adag laakiin sidoo kale aad bay u dhuuban yihiin oo way ku adag yihiin isticmaalka.

Waxaan bixinaa taarikada daanka ee 13%, 18% iyo 22% darajooyinka manganese oo leh chromium u dhexeeya 2%-3%. Fiiri shaxda hoose ee guryahayaga dhimanaya manganese sare:

| Qalab | Halabuurka Kiimikada (%) | Hantida Mashiinka | ||||

|

| Mn | Cr | C | Si | Ak/cm | HB |

| Mn13Cr2 | 12-15 | 1.7-2.2 | 1.15-1.25 | 0.3-0.8 | >140 | ≤220 |

| Mn18Cr2 | 17-19 | 1.8-2.2 | 1.15-1.3 | 0.3-0.8 | >140 | ≤230 |

| Mn22Cr2 | 21-23 | 1.8-2.2 | 1.1-1.4 | 0.3-0.8 | >140 | ≤240 |