LIHLAHISO

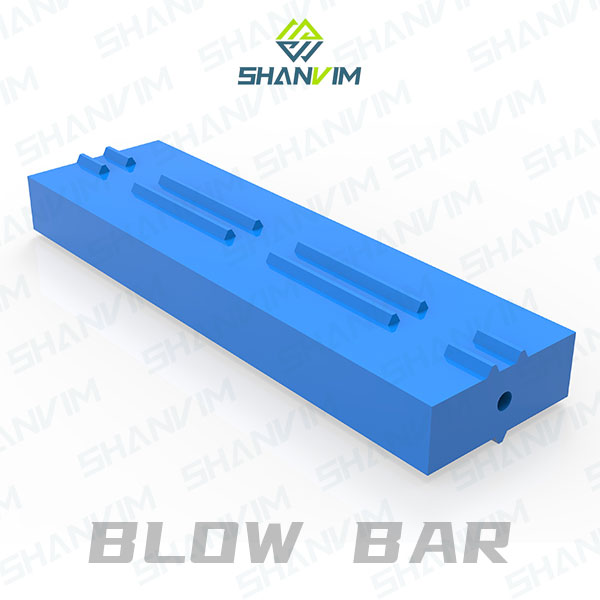

PHAHAMENG MANGANESE SEFUBA BAR

Tlhaloso

Metsuke litšepe tse teteaneng, tseo hangata li leng motsoako oa chrome, tse etselitsoeng morero oa ho arola lisebelisoa tse kang asphalt, konkreite, mokoetla, joalo-joalo.

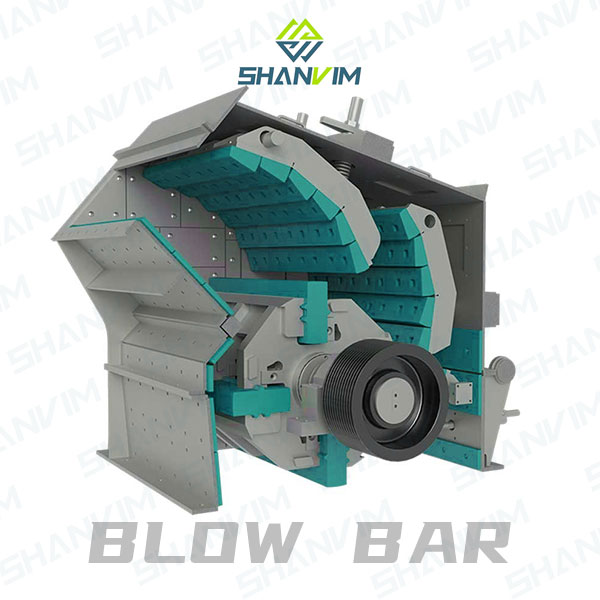

Sefate sa ho phatlohake karolo ea bohlokoa nakong ea ho silakanya karapameng shaft impactor. Lisebelisoa tsa li-blow bars hangata li khethoa ho ea ka mosebetsi oa crusher ea tšusumetso.

Ha li behiloe ka har'a li-crushers tse ts'oanang, li-blow bars li kenngoa ka har'arotorle ho potoloha ka lebelo le phahameng, ho etsa hore kopano eohle ea rotor e otle khafetsa ho otla thepa. Nakong ea ts'ebetso ena, hoseqhoqhofractures thepa ho fihlela e kopana le boholo bo loketseng ho oa kakamore ea crusher.

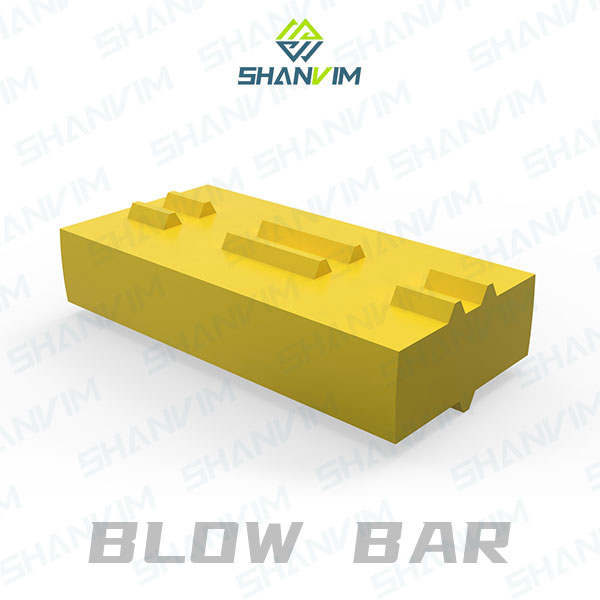

Likarolo tse ling tsa 'Nete tse Sebeletsoeng - Li-Impact Crusher Blow Bars tse entsoeng ke SHANVIM

SHANVIM® e fana ka meralo e fapaneng mme e etsa litharollo tse fapaneng tsa "blowl bar" bakeng sa mefuta e mengata e fapaneng ea li-brand tsa OEM tse tšekaletseng tse kenyelletsang: Hazemag, Mesto, Kleemann, Rockster, Rubble Master, Powerscreen, Striker, Keestrack, McClosky, Eagle, Tesab, Finlay le ba bang. . SHANVIM®"Tlhahiso ea 'Nete"li-blow bars li etselitsoe ho lelefatsa bophelo ba ho roala, ho fana ka mokhoa o phethahetseng o ka feto-fetohang bakeng sa sebapali sa hau, le ho eketsa litefiso tsa tlhahiso haho fokotsa litšenyehelo ka tone.

SHANVIM® Alternative Blow Bars E Fumaneha Bakeng sa Meetso e Ka Tlase e Oeleng

Mehlahare e emeng le e suthehang e ka ba sephara kapa ea masenke. Ka kakaretso, lipoleiti tsa mohlahare li entsoe ka tšepe e phahameng ea manganese e leng thepa e ka sehloohong ea ho roala. High manganese tšepe e boetse e tsejoa e leHadfield manganese tšepe, tšepe eo manganese ea eona e leng holimo haholo le e nang le thepalintho tsa austenitic. Lipoleiti tse joalo ha li thata haholo feela empa li boetse li na le ductile ebile li sebetsa ka thata ha li sebelisoa.

Re fana ka lipoleiti tsa mohlahare ka 13%, 18% le 22% ea limaraka tsa manganese tse nang le chromium ho tloha ho 2% -3%. Sheba tafole e ka tlase ea thepa ea rona e phahameng ea mohlahare oa manganese:

Metallurgy of the Blow Bars

Lisebelisoa tsa SHANVIM crusher blower li fumaneha ka mefuta e fapaneng ea metallurgy ho fana ka litlhoko tsa hau tse ikhethang. Mefuta e mengata ea metallurgy e kenyelletsa Manganese, Chrome e tlase, Chrome e Bohareng, Chrome e Phahameng, Martensitic le Ceramic e kopaneng.

Joalokaha ho bontšitsoe setšoantšong, ho eketseha ha tšepe ea tšepe (bothata) hangata ho tsamaisana le ho fokotseha ha boima (ho hanyetsa tšusumetso) ea thepa.

TŠEPILE MANGANE

Ho hanyetsa ha tšepe ea manganese e nang le sebopeho sa austenitic ho bakoa ke ts'ebetso ea ho thatafala ha mosebetsi. Tšusumetso le khatello ea khatello e fella ka ho thatafala ha sebopeho sa austenitic holim'a metsi. Boima ba pele ba tšepe ea manganese ke hoo e ka bang. 20 HRC. Matla a tšusumetso ke hoo e ka bang. 250J/cm².

Kamora ho thatafala ha mosebetsi, boima ba pele bo ka fihla ho hoo e ka bang. 50 HRC. Likarolo tse tebileng, tse e-s'o thatafatsoe ka tsela eo li fana ka ho tiea ho hoholo ha tšepe ena. Botebo le boima ba libaka tse thata tsa mosebetsi li itšetlehile ka kopo le mofuta oa tšepe ea manganese.

Manganese tšepe e na le histori e telele. Kajeno, tšepe ena e sebelisoa haholo bakeng sa mehlahare e pshatlehang, li-cones le likhetla tse pshatlang (mantle le lijana tsa sekotlolo). Ho crusher ea tšusumetso, ho khothaletsoa feela ho sebelisa li-blow bars tsa manganese ha u sila lisebelisoa tse fokolang haholo le tse kholo haholo (mohlala, limestone).

CHROME TŠEPE

Ka tšepe ea chrome, carbon e kopantsoe ka lik'hemik'hale ka mokhoa oa chromium carbide. Ho hanyetsa ho roala ha tšepe ea chrome ho thehiloe holim'a li-carbide tsena tse thata tsa matrix a thata, moo motsamao o sitisoang ke li-offsets, tse fanang ka matla a phahameng a matla empa ka nako e ts'oanang ho fokotseha ho fokolang.

Ho thibela thepa hore e se ke ea brittle, litšepe tse otlang li tlameha ho phekoloa ka mocheso. Ka hona, ho tlameha ho hlokomeloe hore mocheso le nako ea nako ea annealing li khomaretsoe hantle. Chrome steel hangata e na le ho thatafala ha 60 ho isa ho 64 HRC le matla a tshusumetso a tlase haholo a 10 J/cm².

Ho thibela ho robeha ha mekoallo ea tšepe ea chrome, ho ka 'na ha se ke ha e-ba le lintho tse ke keng tsa senyeha ka har'a thepa ea phepelo.

SHANVIM Chorme Foka Bars Elements

| Sebopeho sa Lik'hemik'hale se Phahameng sa Chrome Casting | |||||||||

| Code Elem | Cr | C | Na | Cu | Mn | Si | Na | P | HRC |

| KmTBCr4Mo | 3.5-4.5 | 2.5-3.5 | / | / | 0.5-1.0 | 0.5-1.0 | / | ≤0.15 | ≥55 |

| KmTBCr9Ni5Si2 | 8.0-1.0 | 2.5-3.6 | 4.5-6.5 | 4.5-6.5 | 0.3-0.8 | 1.5-2.2 | 4.5-6.5 | / | ≥58 |

| KmTBCr15Mo | 13-18 | 2.8-3.5 | 0-1.0 | 0-1.0 | 0.5-1.0 | ≤1.0 | 0-1.0 | ≤0.16 | ≥58 |

| KmTBCr20Mo | 18-23 | 2.0-3.3 | ≤2.5 | ≤1.2 | ≤2.0 | ≤1.2 | ≤2.5 | ≤0.16 | ≥60 |

| KmTBCr26 | 23-30 | 2.3-3.3 | ≤2.5 | ≤2.0 | ≤1.0 | ≤1.2 | ≤2.5 | ≤0.16 | ≥60 |

MATENSITIC TŠEPE

Martensite ke mofuta oa tšepe o nang le carbon-saturated ka ho feletseng o entsoeng ka ho pholile kapele. Ke feela kalafong e latelang ea mocheso moo carbon e tlosoang ho martensite, e ntlafatsang matla le thepa ea ho apara. Ho thatafala ha tšepe ena ho pakeng tsa 44 ho isa ho 57 HRC le matla a tšusumetso lipakeng tsa 100 le 300 J/cm².

Kahoo, mabapi le ho thatafala le ho tiea, litšepe tsa martensitic li pakeng tsa tšepe ea manganese le tšepe ea chrome. Li sebelisoa haeba mojaro oa tšusumetso o le nyane haholo hore o ka thatafatsa tšepe ea manganese, le / kapa ho hanyetsa ho hotle hoa hlokahala hammoho le khatello e ntle ea khatello ea maikutlo.

MATRIX EA TŠEPE E HLAHANG KERAMIC COMPOSITE

Metal Matrix Composites, kopanya khanyetso e phahameng ea matrix ea tšepe le lirafshoa tse thata haholo. Li-preform tsa porous tse entsoeng ka likaroloana tsa ceramic li hlahisoa ts'ebetsong. Boima ba tšepe bo qhibilihisitsoeng bo kenella ka har'a marang-rang a porous ceramic. Boiphihlelo le tsebo li ipapisitse le ts'ebetso ea ho etsa lintho tse peli tse fapaneng - tšepe e nang le botenya ba 7.85 g/cm³ le ceramic e botenya ba 1-3 g/cm³ - li kopantsoe 'me ho na le ho kenella ka botlalo.

Motsoako ona o etsa hore li-blow-bars haholo-holo li se ke tsa senyeha empa ka nako e ts'oanang li hanana le tšusumetso. Ka li-blow bars tse entsoeng ka lihlopha tse tsoang tšimong ea li-ceramics, bophelo ba tšebeletso bo bolelele ba makhetlo a mararo ho isa ho a mahlano ho feta ba tšepe ea martensitic e ka finyelloang.