IIMVELISO

UMANGANESE OPHAKAMILEYO WOBHOVA BAR

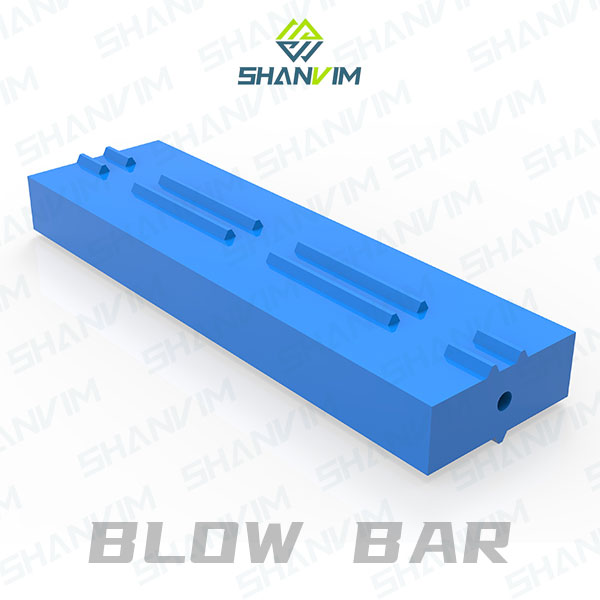

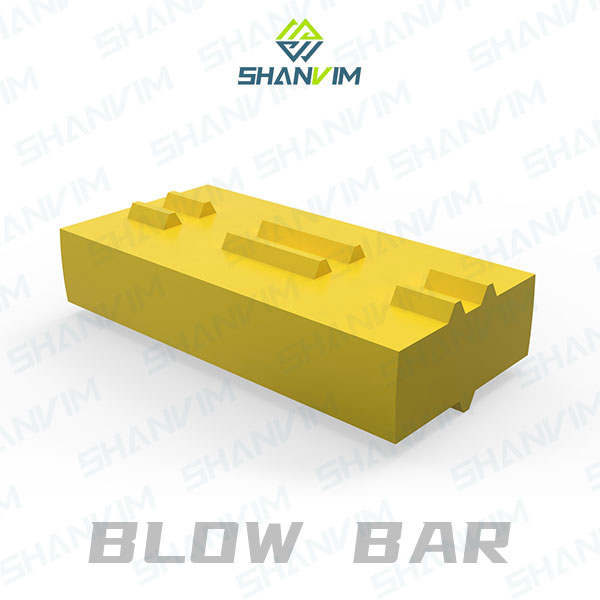

Inkcazo

Imivalo yokuvuthelaNgamaplanga ashinyeneyo esinyithi, ngokwesiqhelo ngumxube othile wechrome, ezenzelwe injongo yokophula ngokufanelekileyo imathiriyeli enjenge asphalt, ikhonkrithi, ikalika, njl.

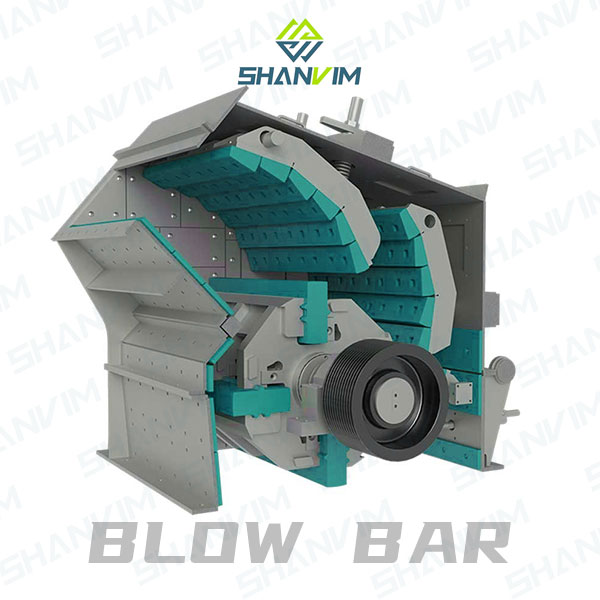

Ibar yokuvuthelayinxalenye ebalulekileyo ngexesha inkqubo yokutyumza ngei-horizontal shaft impactor. Izixhobo zemivalo yokuvuthela zidla ngokukhethwa ngokuhambelana nomsebenzi wokutyumza impembelelo.

Xa ibekwe izityumzi impembelelo oxwesileyo, imivalo blowu ifakwe kwii-rotorkwaye ijikelezwe ngesantya esiphezulu, yenza yonke indibano ye-rotor ijikelezisa ngokuphindaphindiweyo ukubetha izinto. Ngexesha le nkqubo, iibha yokuvuthelafractures imathiriyeli de idibane nobungakanani obufanelekileyo ukuwela ngaphandleimpembelelo kwigumbi lokutyumza.

IiNdawo ezizezinye ezizezinye zokwenyani-Iimpembelelo ze-Crusher Blow Bars ezenziwe ngu-SHANVIM

I-SHANVIM® inikezela ngoyilo olwahlukileyo kwaye yenza izisombululo ezahlukeneyo zebha yokuvuthela kuluhlu olubanzi lwe-OEM ethe tyaba yeempawu zesityumzi eziquka: Hazemag, Mesto, Kleemann, Rockster, Rubble Master, Powerscreen, Striker, Keestrack, McClosky, Eagle, Tesab, Finlay nabanye. . SHANVIM®"Enye indlela yokwenyani"Imivalo yokuvuthela yenzelwe ukwandisa ubomi bokunxiba, ukubonelela ngokutshintshana ngokufanelekileyo kwimpembelelo yakho, kunye nokunyusa amazinga emveliso ngelixa.ukunciphisa iindleko-ngetoni nganye.

IiBha zokuvuthela ezizezinye ze-SHANVIM® ziyafumaneka kwiiModeli eziNgezantsi eziGoqo

Yomibini imihlathi emileyo kunye neshukumayo inokufa inokuba sicaba okanye ibhebhetheke. Ngokubanzi, iipleyiti zemihlathi zenziwe ngentsimbi ephezulu yemanganese eyona nto inxibayo. Intsimbi yemanganese ephezulu yaziwa ngokubaHadfield manganese intsimbi, intsimbi enomxholo wemanganese uphezulu kakhulu kwaye inayoiimpawu ze-austenitic. Iipleyiti ezinjalo aziqine kakhulu kuphela kodwa zikwayi-ductile kwaye zisebenza nzima xa zisetyenziswa.

Sinika iipleyiti zemihlathi kwi-13%, 18% kunye ne-22% yamabanga e-manganese kunye ne-chromium ukusuka kwi-2% -3%. Jonga ngezantsi itheyibhile yeepropathi zethu zokufa kwemihlathi ephezulu yemanganese:

I-Metallurgy ye-Blow Bars

Imivalo ye-SHANVIM yokutyumza iyafumaneka kwiintlobo ngeentlobo zesinyithi ukulungiselela iimfuno zakho zokutyumza ezizodwa. Uluhlu lwe-metallurgy lubandakanya iManganese, i-Chrome ephantsi, i-Medium Chrome, i-High Chrome, i-Martensitic kunye ne-Composite Ceramic.

Njengoko kubonisiwe kumzobo, ukunyuka kwentsimbi yokuxhatshazwa kwentsimbi (ubunzima) ngokuqhelekileyo kuhamba kunye nokunciphisa ukuqina (ukuchasana kwempembelelo) yezinto eziphathekayo.

INKANTSI YOMANGANESE

Ukumelana nokunxiba kwentsimbi ye-manganese kunye nesakhiwo se-austenitic kubangelwa yinto yokuqina komsebenzi. Impembelelo kunye nomthwalo wengcinezelo kubangela ukuqina kwesakhiwo se-austenitic phezu komhlaba. Ubulukhuni bokuqala bentsimbi yemanganese bumalunga. 20 HRC. Amandla empembelelo malunga. 250J/cm².

Emva kokuqina komsebenzi, ubunzima bokuqala bunokufikelela kwi-approx. 50 HRC. Iileya ezinzulu, ezingekaqini ngoko zibonelela ngokuqina okukhulu kwale ntsimbi. Ubunzulu kunye nobunzima beendawo ezinobunzima bokusebenza buxhomekeke kwisicelo kunye nohlobo lwensimbi ye-manganese.

Intsimbi yeManganese inembali ende. Namhlanje, le ntsimbi isetyenziswa ikakhulu kwimihlathi yokutyumza, iicones ezityumzayo kunye namaqokobhe okutyumza (iingubo kunye neelitha zesitya). Kwisixhobo sokutyumza, kucetyiswa kuphela ukuba kusetyenziswe imivalo yokuvuthela yemanganese xa ucumza izinto ezingaqhubi kakhulu kunye nesondlo esikhulu kakhulu (umz. ilitye likalikalika).

Intsimbi ye-CHROME

Ngentsimbi ye-chrome, ikhabhoni iboshwe ngamachiza ngendlela ye-chromium carbide. Ukumelana nokunxiba kwentsimbi ye-chrome kusekelwe kula ma-carbides anzima e-matrix enzima, apho ukunyakaza kuthintelwe yi-offsets, ebonelela ngeqondo eliphezulu lamandla kodwa kwangaxeshanye ubunzima obuncinci.

Ukuthintela ukuba izinto eziphathekayo zingabi brittle, imivalo yokuvuthela kufuneka iphathwe ngobushushu. Kufuneka ke ngoko kuqwalaselwe ukuba iqondo lobushushu kunye neeparamitha zexesha lokuvalela zithotyelwe ngokuthe ngqo. Intsimbi yeChrome ikholisa ukuba nokuqina kwe-60 ukuya kwi-64 HRC kunye namandla empembelelo ephantsi kakhulu ye-10 J/cm².

Ukuthintela ukuphulwa kweentsimbi ze-chrome ezivuthelayo, akunakubakho naziphi na izinto ezingenakunqanyulwa kwizinto zokutya.

SHANVIM Chorme Vuthela iiBha Elements

| Ukwakhiwa kweMichiza ye-Chrome ePhakamileyo | |||||||||

| Ikhowudi Elem | Cr | C | Na | Cu | Mn | Si | Na | P | HRC |

| KmTBCr4Mo | 3.5-4.5 | 2.5-3.5 | / | / | 0.5-1.0 | 0.5-1.0 | / | ≤0.15 | ≥55 |

| KmTBCr9Ni5Si2 | 8.0-1.0 | 2.5-3.6 | 4.5-6.5 | 4.5-6.5 | 0.3-0.8 | 1.5-2.2 | 4.5-6.5 | / | ≥58 |

| KmTBCr15Mo | 13-18 | 2.8-3.5 | 0-1.0 | 0-1.0 | 0.5-1.0 | ≤1.0 | 0-1.0 | ≤0.16 | ≥58 |

| KmTBCr20Mo | 18-23 | 2.0-3.3 | ≤2.5 | ≤1.2 | ≤2.0 | ≤1.2 | ≤2.5 | ≤0.16 | ≥60 |

| KmTBCr26 | 23-30 | 2.3-3.3 | ≤2.5 | ≤2.0 | ≤1.0 | ≤1.2 | ≤2.5 | ≤0.16 | ≥60 |

Intsimbi yeMARTENSITIC

I-Martensite luhlobo lwe-iron egcwele i-carbon eyenziwe ngokupholisa ngokukhawuleza. Kuphela kunyango olulandelayo lokutshisa ukuba ikhabhoni isuswe kwi-martensite, ephucula amandla kunye neempawu zokugqoka. Ukuqina kwale ntsimbi kuphakathi kwe-44 ukuya kuma-57 HRC kunye namandla empembelelo phakathi kwe-100 kunye ne-300 J/cm².

Ngaloo ndlela, malunga nobunzima kunye nokuqina, iintsimbi ze-martensitic zilala phakathi kwentsimbi ye-manganese kunye nentsimbi ye-chrome. Ziyasetyenziswa ukuba umthwalo wempembelelo uncinci kakhulu ukwenza lukhuni intsimbi ye-manganese, kunye / okanye ukuxhathisa okulungileyo kuyafuneka kunye nefuthe elihle lokuxhathisa uxinzelelo.

IMATRISI YEMETALI ENEZIXAKI ZECERAMIC

I-Metal Matrix Composites, idibanisa ukuxhathisa okuphezulu kwe-matrix yentsimbi kunye neekeramics ezinzima kakhulu. I-porous preforms eyenziwe ngamaqhekeza e-ceramic iveliswa kwinkqubo. Ubunzima besinyithi obutyhidiweyo bungena kwinethiwekhi ye-ceramic eneporous. Amava kunye nolwazi lukhethekileyo kwinkqubo yokuphosa apho izinto ezimbini ezahlukeneyo - intsimbi enobunzima obuyi-7.85 g/cm³ kunye ne-ceramic enobunzima obuyi-1-3 g/cm³ - zidityanisiwe kwaye kukho ukungena ngokucokisekileyo.

Le ndibaniselwano yenza ukuba imivalo yokuvuthela ikwazi ukumelana nokunxiba kodwa kwangaxeshanye ixhathise kakhulu. Ngeentsimbi zokuvuthela ezenziwe ngee-composites ezivela kwintsimi yeekeramics, ubomi benkonzo obuphindwe kathathu ukuya kahlanu ixesha elide njengoko lentsimbi ye-martensitic inokufezekiswa.