-

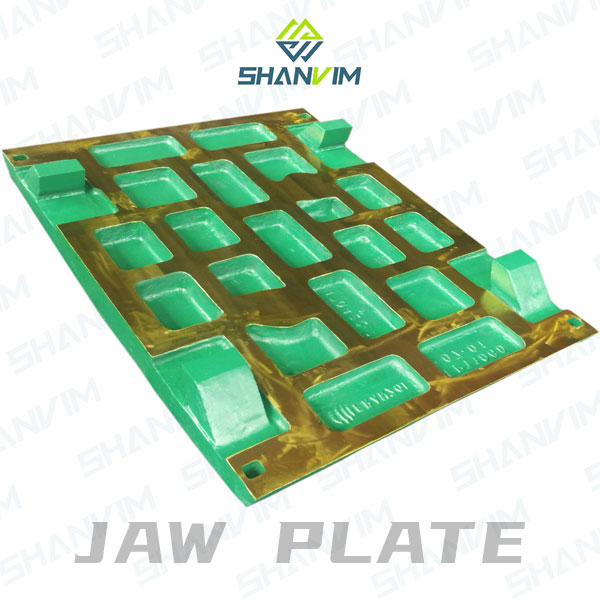

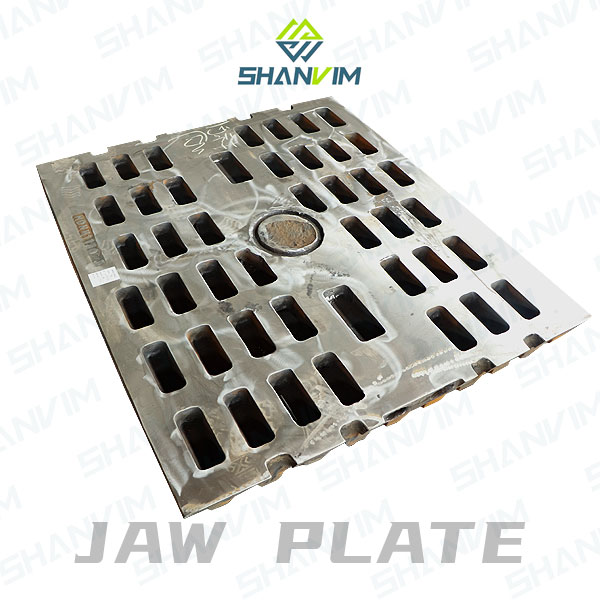

IPLATE YOMHLATHI-EMPHEZULU

I-SHANVIM yokutshintsha imihlathi ye-crusher yenziwe ukuba ihlale ixesha elide kwaye ityumke ngokufanelekileyo, ngelixa inciphisa ukuguga kunye nokukrazula kwisityuli.

Imihlathi yokutyumza ivelisa umgangatho ophucukileyo wamatye ngokuthe gqolo kunemihlathi yesixhobo soqobo esisemgangathweni, ngelixa kuncitshiswa imfuno yokuhlolwa kwakhona kunye nokutyumza kwakhona. I-SHANVIM ibonelela ngoluhlu olupheleleyo lokhetho kuzo zonke izityumli zemihlathi ezidumileyo, kubandakanywa uyilo lwamazinyo olwahlukeneyo, iigophe kunye nealloys.

-

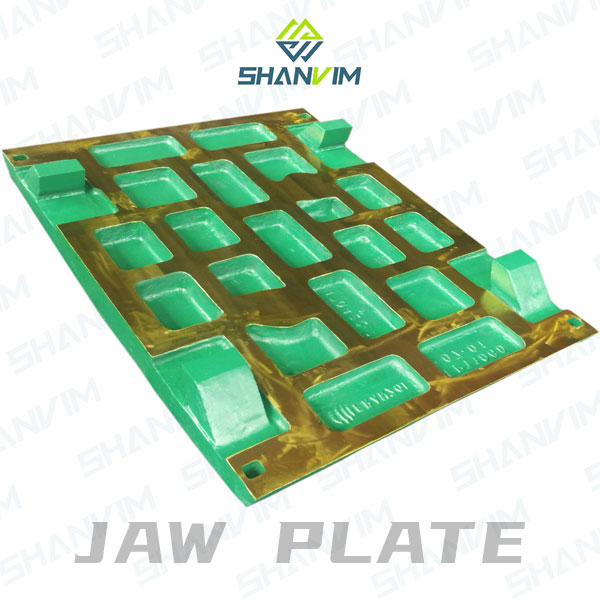

IPLATE YOMHLAYA YE CRUSHER YOMHLATHI

I-SHANVIM ibonelela ngeentsimbi zemihlathi ezenziwe ngentsimbi yemanganese, ezilungele izityumzi zemihlathi ezahlukeneyo kwihlabathi jikelele. Ukubonelela ngeenxalenye kunye nenkxaso yobugcisa bezemigodi, iaggregate, kunye neshishini lokurisayikilisha emva kwemarike. -

IIpleyiti zemihlathi YEMIGODI INDUSTRI

I-Jaw crusher isetyenziselwa ubukhulu becala ukutyumza okuphakathi kwezinto ezikrwada kunye nezixhobo ezininzi, ezisetyenziswa kakhulu kwimigodi, isinyithi, izixhobo zokwakha, iindlela, oololiwe, ukongiwa kwamanzi kunye namashishini amachiza. Eyona nto iphezulu yokutyumza yi-320MPa. Iindawo zokutyumza imihlathi nazo zingabhekiswa njengeenxalenye zokunxiba zemihlathi, yinxalenye ebalulekileyo yesityuli somhlathi; Sinokubonelela ngeentlobo ezahlukeneyo zeendawo zokunxiba ze-jaw crusher, ezinje ngepleyiti esisigxina yomhlathi, ipleyiti eshukumayo yomhlathi, ipleyiti yokuguqula, ipleyiti ye-liner, kodwa nangokwemizobo ebonelelwa ngabathengi ukwenza iimveliso zemathiriyeli ezahlukeneyo. -

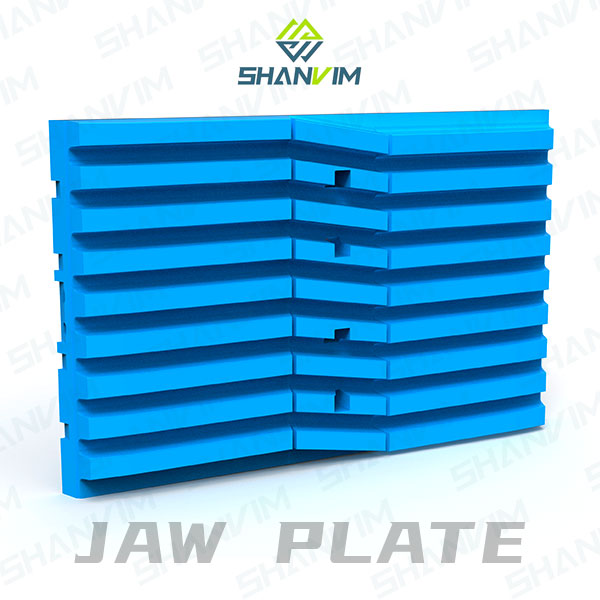

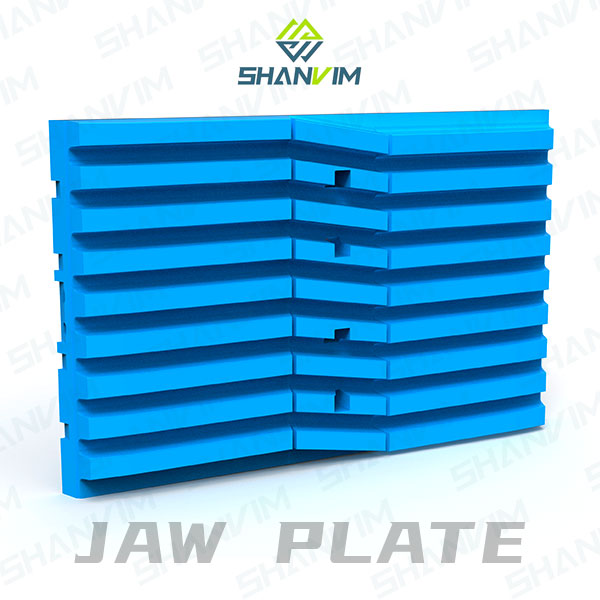

UMHLATHI CRUSHER PLATE-JAW LIER

Iipleyiti zemihlathi okanye i-Jaw Dies zezona nxalenye zokunxiba ezihlala zitshintshwa zesityuli somhlathi, ngoko umgangatho wokufa kwemihlathi yenye yezona zinto zibalulekileyo ezimisela ukusebenza kakuhle kunye nexesha lokusebenza.

Iseti yeepleyiti zemihlathi zenziwe ngezinto ezinokususwa (umhlathi ojingi) kunye nepleyiti yomhlathi esisigxina (umhlathi omileyo). Ukucinezelwa kwezinto ezityumzwayo kwisityuli somhlathi kufezekiswa xa ifa lomhlathi elishukumayo licinezela umxhesho wokufa kwemihlathi esisigxina. Ilitye lihlala emhlathini womatshini wokutyumza de libe lincinci ngokwaneleyo ukudlula kwi-gap ukuya emazantsi emihlathi. -

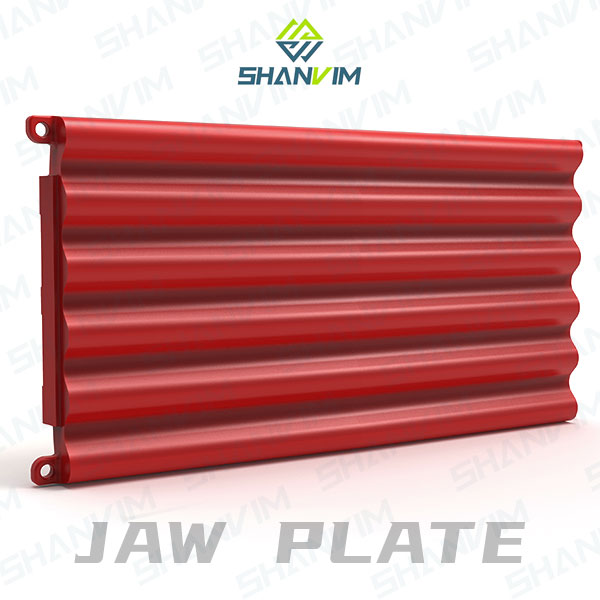

I-BI-METAL COMPOSITE HLAW PLATE

Ngokubhekiselele kumgaqo wokusebenza wesityumzi somhlathi kunye nemeko yokusetyenziswa kwayo, umhlathi wokugalela we-bimetallic ophindwe kabini we-bimetallic waphuhliswa. Ubuso obusebenzayo benziwe ngentsimbi ye-alloy kunye nokuxhatshazwa okuphezulu. I-lining yenziwe ngentsimbi etyhidiweyo enempembelelo entle, Nika umdlalo opheleleyo kwiimpawu zezinto ezahlukeneyo. Ngelo xesha, inkqubo yokugalela ekhethekileyo kunye nenkqubo yokugalela iqinisekisa iyunifomu kunye nojongano olupheleleyo lwezinto ezidibeneyo kunye nokwandisa ukusebenza kwenkonzo yepleyiti yomhlathi.

-

I-TIC FAKA Ipleyiti yomhlathi

Ukusetyenziswa kwentsimbi ephezulu-manganese okanye ipleyiti yomhlathi ephezulu yemanganese njengesiseko semathiriyeli, kwindawo yabo yokusebenza idityanisiwe ye-carbide ehlanganisiweyo, i-bi-metal composite edityanisiweyo yamalungu okunxiba umphezulu inokumelana nokunxiba okugqwesileyo, indawo enganxibanga eneplastiki egqwesileyo kunye nefuthe. ubunzima. Ifakwe ngumsebenzisi ukuba isetyenziswe, ibonakalisa iziphumo ezilungileyo.

-

IPLATE YOMHLATHI-UBUDE

SHANVIM imihlathi yokutyumza ikunika:

Imiphezulu eyenziwe ngoomatshini ukuze ilingane kunye nokuphazamiseka okuncinci kunye nexesha lokuphumla.

Ukhetho olukhulu lwezinyo kunye nolungelelwaniso lwegophe ukwenzela ukusebenza ngokugqibeleleyo kuso nasiphi na isicelo

Iialloyi ezingagqithwanga zobomi obude bokunxiba kunye neendleko eziphantsi ngetoni nganye.

Ngokwengxelo evela kubathengi, ukusebenza kakuhle kwamalungu e-Jaw crusher akwimo yokusebenza eyohlukeneyo kulihlise kakhulu ixesha loviwo kunye nokulungiswa kunye neendleko zokusebenzisa.

-

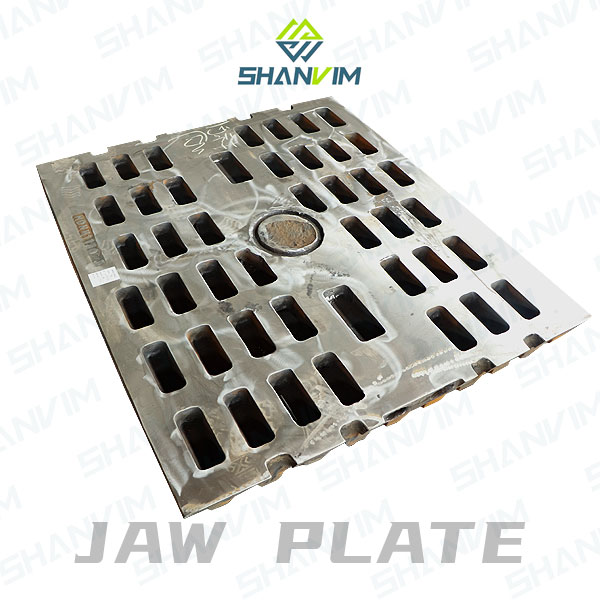

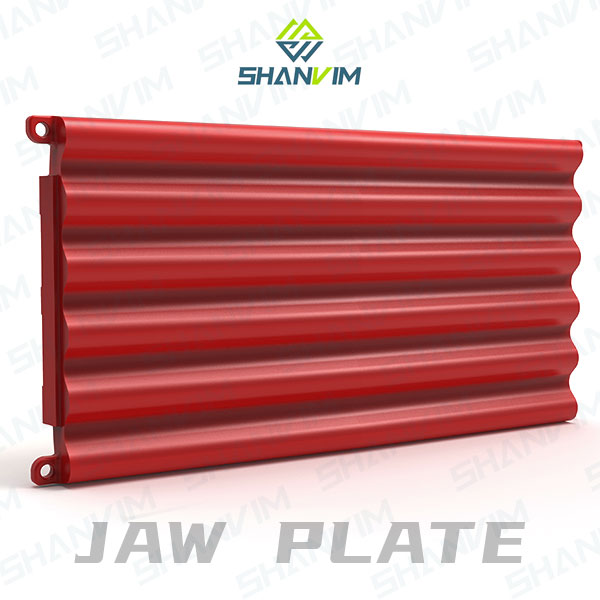

Ipleyiti yomhlathi EYENZIWE NGEMANGANESE EPHAKAMILEYO

Intsimbi ye-manganese ephezulu yinto yendabuko yeplate yomhlathi, kuba inokuqina okulungileyo kunye nokukwazi ukuqina kwe-deformation. Ngokomxholo wento, Mn13%,Mn13%,Cr2%,Mn18%,Mn18%Cr2%,Mn22%Cr2%.Okanye ngokwezithako ezikhethekileyo phantsi kweemeko zokusebenza, ipleyiti yomhlathi we-alloy encinci yensimbi ephezulu yemanganese isityumzi eveliswe ngu Zhejiang Shanvim unomsebenzi omhle, izithako ezingqongqo kunye nonyango kwindawo yobushushu. -

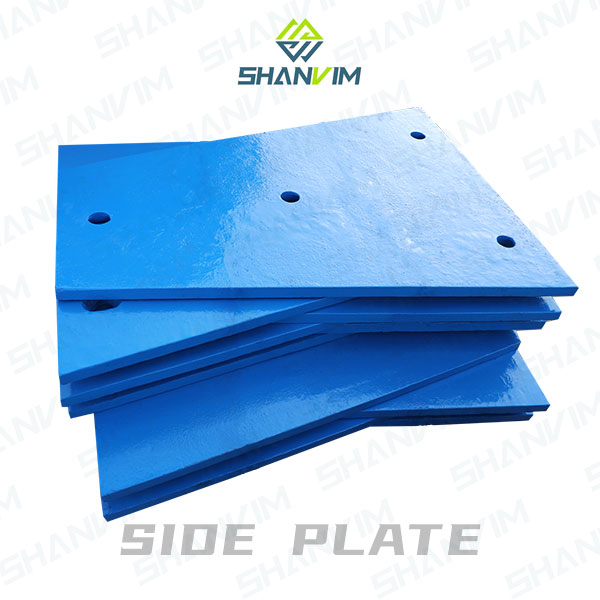

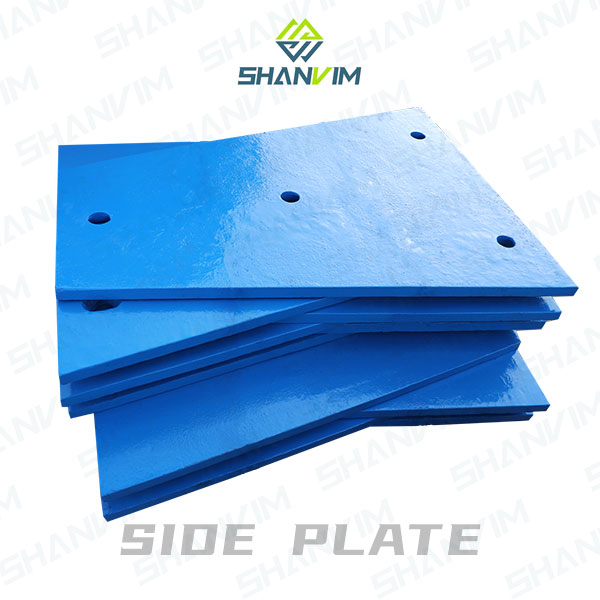

I-RAW CRUSHER WAR PLATE-SIDE PLATE

I-SHANVIM- uMboneleli wakho oThembekileyo waMacandelo eMithi yokutyumza

Iindawo ezisecaleni ze-SHANVIM zemihlathi kunye nezinto zokunxiba zisetyenzisiwe kwaye zamkelwa ngabaqhubi bemihlathi emhlabeni jikelele. Sifikelele kwizivumelwano kunye neenkampani ezininzi zemigodi ezidumileyo kwihlabathi, kwaye ziye zachongwa njengababoneleli beendawo zabo zokutyumza imihlathi. -

IIPLATES ZENYE YEZICALA EZINGUNDOQO ZOKUTSHA UTSHINTSHO LWEMIHLAYA CRUSHER.

Kutheni Khetha iipleyiti ezisecaleni zeSHANVIM

① Uvavanyo lomgangatho wemveliso: uvavanyo lokuqina, ubume bemetallographic, uvavanyo lokwenziwa koomatshini, uhlolo lwe-ultrasonic, i-high frequency infrared carbon kunye nohlalutyo lomphezulu njl.njl.

② Iimveliso ezikhuphisanayo: umgangatho olungileyo kunye nexabiso elifanelekileyo.

③ Ukuxhathisa okuqinileyo kunye nobude bobomi obude, bunokusetyenziswa kwindawo enzima kunye nokukrala okunzulu.

④ Ubuchwephesha: umzi-mveliso wethu uneminyaka engaphezulu kwe-20 yamava okusebenza ekwenziweni kunye nokwenza inkqubo kunye nokwenza.

⑤ Singabonelela ngoyilo olulungelelanisiweyo ngokweemfuno zabaxumi bethu kwaye sisulungekise iimveliso zethu ngempendulo yabathengi bethu. -

Ipleyiti EZIQINISEKILEYO YOMHLATHI YE-CRUSHER YOMHLATHI

Iindawo ezisecaleni zeCrusher zenziwe ngentsimbi ephezulu yemanganese iMn13Cr2, Mn18Cr2, Mn22Cr2 okanye intsimbi yemanganese enealloyi ekhethekileyo kunye nenkqubo yokunyanga ubushushu. Izitshixo zomhlathi wemihlathi zinobomi obusebenzayo be-10% -15% ubude kunezo zenziwe ngentsimbi yemveli yemanganese.