IMIKHIQIZO

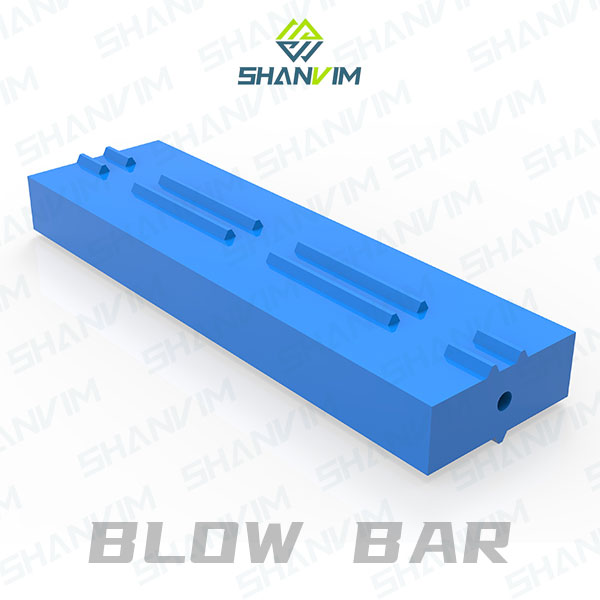

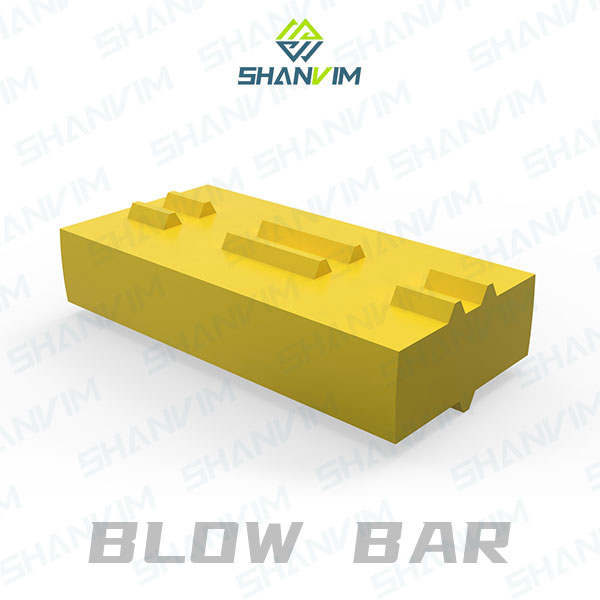

UMANGANESE OKUPHAKAMILEYO WOKUSHAYA IBHA

Incazelo

Vuthela imigoqoama-slabs aminyene ensimbi, ngokuvamile ingxube ethile ye-chrome, akhiwe ngenjongo yokuhlukanisa izinto ezifana netiyela, ukhonkolo, i-limestone, njll.

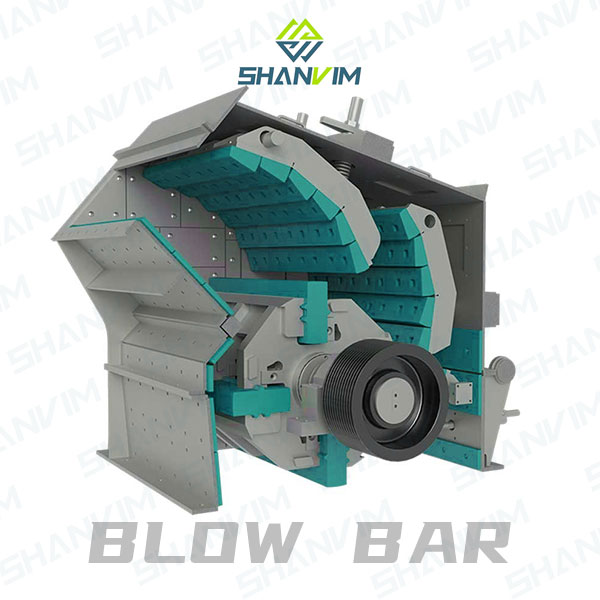

Ibha yokuvuthelakuyingxenye ebalulekile phakathi nenqubo yokuchoboza ngei-horizontal shaft impactor. Izinto zokushaywa kwezinsimbi ngokuvamile zikhethwa ngokuya ngomsebenzi we-crusher enomthelela.

Uma isethwe kuma-crushers avundlile, ama-blow bars afakwa ku-i-rotorfuthi ijikelezwe ngesivinini esikhulu, okwenza wonke umhlangano we-rotor ujikeleze ngokuphindaphindiwe ukushaya into. Phakathi nale nqubo, iibha yokushayaiphula izinto kuze kube yilapho ihlangabezana nosayizi ofanele ukuze iwele ngaphandlenomthelela ekamelweni le-crusher.

Izingxenye Zangempela Ezihlukile Ezingezinye - Amabha Wokushaywa Kwe-Impact Enziwe Ngu-SHANVIM

I-SHANVIM® inikeza imiklamo ehlukene futhi yenza izixazululo ezihlukahlukene ze-blow bar yohlu olubanzi lwemikhiqizo ye-OEM evundlile ye-crusher ehlanganisa: Hazemag, Mesto, Kleemann, Rockster, Rubble Master, Powerscreen, Striker, Keestrack, McClosky, Eagle, Tesab, Finlay nabanye. . I-SHANVIM®"Enye indlela yangempela"Imishayo yokuqhuma iklanyelwe ukunweba impilo yokuguga, inikeze ukulingana okuphelele okushintshekayo komenzi wakho, futhi kukhuphule amanani okukhiqiza ngenkathiukwehla kwezindleko ngethani.

I-SHANVIM® Alternative Blow Bars Iyatholakala Kumamodeli Angezansi Ayawa

Kokubili umhlathi omile nonyakazayo ungase ube isicaba noma uthayela. Ngokuvamile, amapuleti emihlathi enziwe ngensimbi ephezulu ye-manganese okuyizinto zokugqoka ezivelele. High manganese steel yaziwa nangokuthiInsimbi ye-Hadfield manganese, insimbi okunemanganese yayo kuphezulu kakhulu futhi enayoizakhiwo ze-austenitic. Amapuleti anjalo awaqinile nje kuphela kodwa futhi ane-ductile futhi asebenza kanzima uma esetshenziswa.

Sinikeza amapuleti emihlathi ngamabanga angu-13%, 18% kanye nama-22% e-manganese ane-chromium esukela ku-2% -3%. Bheka ithebula elingezansi lezinto zethu zokufa zomhlathi we-manganese:

I-Metallurgy ye-Blow Bars

Imishayo ye-SHANVIM crusher blower iyatholakala ngezinhlobonhlobo zensimbi ukuze kuhlangatshezwane nezidingo zakho eziyingqayizivele zokuchoboza. Uhlu lwe-metallurgy luhlanganisa iManganese, i-Chrome ephansi, i-Medium Chrome, i-High Chrome, i-Martensitic ne-Composite Ceramic.

Njengoba kuboniswe emfanekisweni, ukwanda kokumelana nokugqoka kwensimbi (ukuqina) kuvame ukuhambisana nokunciphisa ukuqina (ukumelana nomthelela) wezinto ezibonakalayo.

IZINSIMBI zikaMANGANESE

Ukumelana nokugqokwa kwensimbi ye-manganese enesakhiwo se-austenitic kungenxa yesenzo sokuqina komsebenzi. Umthelela nomthwalo wengcindezi kubangela ukuqina kwesakhiwo se-austenitic ebusweni. Ubulukhuni bokuqala bensimbi ye-manganese cishe. 20 HRC. Amandla womthelela cishe. 250J/cm².

Ngemuva kokuqiniswa komsebenzi, ubulukhuni bokuqala bungakwazi ukufinyelela ku-approx. 50 HRC. Izingqimba ezijulile, ezingakaqini, ngaleyo ndlela zihlinzekela ukuqina okukhulu kwale nsimbi. Ukujula nobulukhuni bezindawo eziqinisiwe kuncike ekusetshenzisweni nasekuhlobeni kwensimbi ye-manganese.

Insimbi yeManganese inomlando omude. Namuhla, le nsimbi isetshenziswa kakhulu emihlathini ye-crusher, ama-cone okuchoboza kanye namagobolondo okuchotshozwa (iziphuku & nezitsha zesitsha). Kumshini wokugaya umthelela, kutuswa kuphela ukusebenzisa izinsimbi ze-manganese lapho uchoboza okuphakelayo okungaxubeki nokukhulu kakhulu (isb. i-limestone).

I-CHROME STEEL

Ngensimbi ye-chrome, ikhabhoni iboshwe ngamakhemikhali ngendlela ye-chromium carbide. Ukumelana nokugqoka kwensimbi ye-chrome kusekelwe kulawa ma-carbides aqinile we-matrix eqinile, lapho ukunyakaza kuvinjelwa khona ama-offsets, okunikeza izinga eliphezulu lamandla kodwa ngesikhathi esifanayo ukuqina okuncane.

Ukuze uvimbele ukwakheka kwe-brittle, imigoqo yokushaywa kufanele iphathwe ngokushisa. Ngakho-ke kufanele kuqashelwe ukuthi izinga lokushisa kanye nemingcele yesikhathi sokudonsa kulandelwa ncamashi. Insimbi ye-Chrome ngokuvamile inobunzima obungu-60 kuya ku-64 HRC namandla omthelela aphansi kakhulu angu-10 J/cm².

Ukuze uvimbele ukuphuka kwezinsimbi zensimbi ze-chrome, kungase kungabi khona noma yiziphi izici ezinganqamuki kokuphakelayo.

Izingxenye ze-SHANVIM Chorme Blow Bars

| Ukwakheka Kwekhemikhali Yokusakaza Ye-Chrome Ephezulu | |||||||||

| Ikhodi Elem | Cr | C | Na | Cu | Mn | Si | Na | P | HRC |

| I-KmTBCr4Mo | 3.5-4.5 | 2.5-3.5 | / | / | 0.5-1.0 | 0.5-1.0 | / | ≤0.15 | ≥55 |

| I-KmTBCr9Ni5Si2 | 8.0-1.0 | 2.5-3.6 | 4.5-6.5 | 4.5-6.5 | 0.3-0.8 | 1.5-2.2 | 4.5-6.5 | / | ≥58 |

| I-KmTBCr15Mo | 13-18 | 2.8-3.5 | 0-1.0 | 0-1.0 | 0.5-1.0 | ≤1.0 | 0-1.0 | ≤0.16 | ≥58 |

| KmTBCr20Mo | 18-23 | 2.0-3.3 | ≤2.5 | ≤1.2 | ≤2.0 | ≤1.2 | ≤2.5 | ≤0.16 | ≥60 |

| KmTBCr26 | 23-30 | 2.3-3.3 | ≤2.5 | ≤2.0 | ≤1.0 | ≤1.2 | ≤2.5 | ≤0.16 | ≥60 |

I-MARTENSITIC STEEL

I-Martensite iwuhlobo lwensimbi olugcwele ikhabhoni elenziwa ngokupholisa ngokushesha. Kuphela ekwelashweni kokushisa okulandelayo lapho i-carbon ikhishwa ku-martensite, okuthuthukisa amandla nokugqoka izakhiwo. Ukuqina kwale nsimbi kufinyelela phakathi kuka-44 kuya ku-57 HRC namandla okushayisana phakathi kuka-100 no-300 J/cm².

Ngakho, mayelana nobulukhuni nokuqina, izinsimbi ze-martensitic zilele phakathi kwensimbi ye-manganese nensimbi ye-chrome. Zisetshenziswa uma umthwalo womthelela umncane kakhulu ukuze uqinise insimbi ye-manganese, kanye/noma ukumelana nokugqokwa okuhle kuyadingeka kanye nomthelela omuhle wokumelana nengcindezi.

I-MATRIX YE-METAL ENEZINKHIMBA ZOKUTHOLA

I-Metal Matrix Composites, ihlanganisa ukumelana okuphezulu kwe-matrix yensimbi nezinsimbi zobumba eziqine kakhulu. Ama-preforms anezimbotshana ezenziwe ngezinhlayiya ze-ceramic akhiqizwa kule nqubo. Inqwaba yensimbi encibilikisiwe ingena kunethiwekhi ye-ceramic enezimbotshana. Okwenziwayo nolwazi luqondene ngqo nenqubo yokulingisa lapho izinto ezimbili ezihlukene - insimbi enokuqina okungu-7.85 g/cm³ kanye ne-ceramic enogqinsi luka-1-3 g/cm³ - kuhlanganiswe futhi kube nokungena kahle.

Le nhlanganisela yenza imigoqo yokuqhuma ikakhulukazi imelane nokugqokwa kodwa ngesikhathi esifanayo imelane nomthelela. Ngemigoqo yokuqhuma eyenziwe ngezinhlanganisela ezivela emkhakheni wezitsha zobumba, impilo yesevisi ephindwe kathathu kuya kahlanu ubude uma leyo yensimbi ye-martensitic ingafinyelelwa.